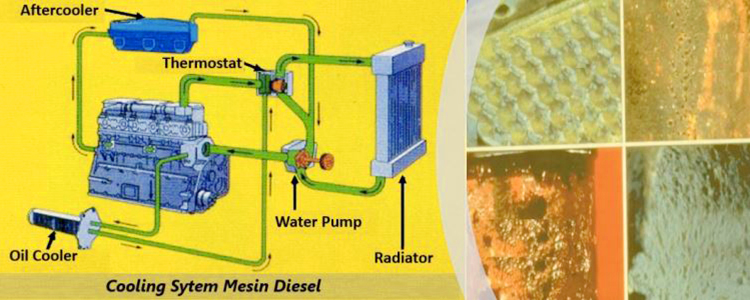

Radiator coolant products for diesel engines in the mining industry play a very vital role for heavy-duty engine units. This product functions to absorb heat in the engine’s cooling system. If the radiator coolant does not work optimally, the cooling system’s performance will not be maximized.

In the field, there are often many problems with this cooling system, such as :

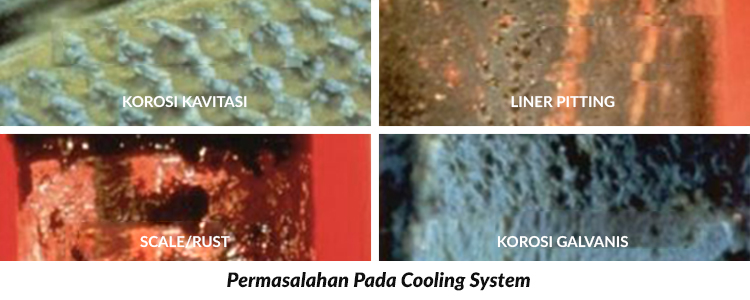

- Cavitation corrosion, caused by the repeated bursting of air bubbles on the metal surface, forming holes on the metal surface

- Pitting corrosion, caused by the entry of air into the cooling system

- Galvanic corrosion, caused by the potential difference between two metals

- Scale/rust in the cooling system

These problems are often caused by improper use of radiator coolant for diesel engines. If left unchecked, it can be very dangerous as it can cause radiator leaks, pump failures, and clogged cooling channels due to scale, resulting in engine overheating.

Causes of Problems

Did you know that the causes of the above problems often stem from seemingly trivial matters that you might never have guessed? Here are the things you must avoid…

- Not refilling

A decrease in the volume of radiator coolant for diesel engines reduces corrosion protection in the system. This is caused by leakage or evaporation. If not refilled, it will cause significant problems. - Not performing service intervals

Service intervals aim to ensure that the additives and glycol in the coolant can still provide corrosion protection in the system. It is also to check whether the coolant needs to be replaced. - Using improper sealing additives

Using random anti-leak chemicals will cause contamination, making your diesel engine radiator coolant not work optimally - Using soluble oil

Because it is soluble, this type of oil can dissolve in the diesel engine radiator coolant and disrupt the cooling system - Filling with low-quality water

This action primarily causes scale formation, and the coolant additives do not function properly - Using regular coolant

Coolants that do not meet ASTM 6210 and ASTM D4985 standards are certainly not guaranteed in quality

Solution

Eonchemicals offers solutions with products that meet ASTM standards and services (onsite service & analysis) to ensure that radiator coolant can work optimally.

Read related article : Characteristics of Good Radiator Coolant

Is your diesel engine radiator coolant performance not optimal? We offer free consultations for you, please chat with us.

Consult with EON Now

We are ready to listen and provide the right chemical solution for you. Consultation with our experts is free!

Home

Home