Tramp oil is oil from CNC machines that mixes with coolant. The more tramp oil there is, the more oil gets emulsified in the coolant. Consequently, it becomes necessary to drain the coolant from CNC machines more frequently. The presence of tramp oil also allows bacteria to grow, causing unpleasant odors. Additionally, CNC machines become dirty, requiring frequent cleaning, which sacrifices both machine productivity and manpower productivity.

Solution

To address this issue, Eonchemicals offers a solution with its product EonTrim C385MS, a synthetic type coolant that provides the following benefits:

- Excellent tramp oil rejection, preventing tramp oil from easily emulsifying with the coolant

- Low coolant carry-off, making coolant usage more efficient

Success Story

An automotive company once faced significant issues with tramp oil. Eonchemicals provided a solution through the following steps:

- Draining and thoroughly cleaning the CNC machines

- Refilling with EonTrim C385MS coolant solution at a 5% concentration

- Conducting a 30-day trial period as agreed

Trial Results

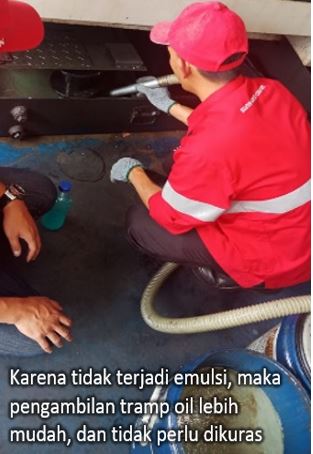

After 30 days, tramp oil did not emulsify with the coolant (it floated), making it easy to clean the tramp oil without the need for draining.

Conclusion

The trial results of the EonTrim C385MS product successfully resolved the tramp oil issue in CNC machines. The user was highly satisfied and recommended gradually replacing the existing coolant with EonTrim C385MS across all CNC machines in their plant to tackle the tramp oil problem.

For (free) consultation on tramp oil solutions for your company, please contact us.

Consult with EON Now

We are ready to listen and provide the right chemical solution for you. Consultation with our experts is free!

Home

Home