The pickling line process in the steel industry aims to remove stubborn contaminants from the surface of metal strips. This process involves immersing the strips in strong acid (HCl), rinsing, and rolling the strips. The rinsing step is intended to remove the strong acid from the strip surface to prevent rusting issues.

The pickling line activity can be halted due to strip splicing or other issues, resulting in parts of the strip not undergoing the rinsing process. This leads to the problem of stoppage marks (rust issues) due to residual acid on the strip surface.

Stoppage marks cause the strip surface to be unclean and lower the grade of the produced coil, thereby reducing its market value..

Stoppage marks on the strip surface

Solution

The stoppage mark issue is often addressed by running the strip backward to undergo the pickling process again. This method risks over-pickling, which can lead to excessive erosion or even break the strip.

A practical and safe solution is to apply an anti-rust agent when the pickling process is halted. This anti-rust agent can neutralize the residual strong acid, preventing the formation of rust spots (stoppage marks) on the strip surface.

Success Story

To address the stoppage mark problem, Eonchemicals provides a solution with the use of StopMark W205 during pickling line stoppages. This product contains a blend of selected anti-rust agents that offer strong protection against stoppage marks when the pickling line temporarily halts.

Based on test results, a concentration of just 0.5% StopMark W205 is sufficient to prevent the appearance of stoppage marks on the metal surface

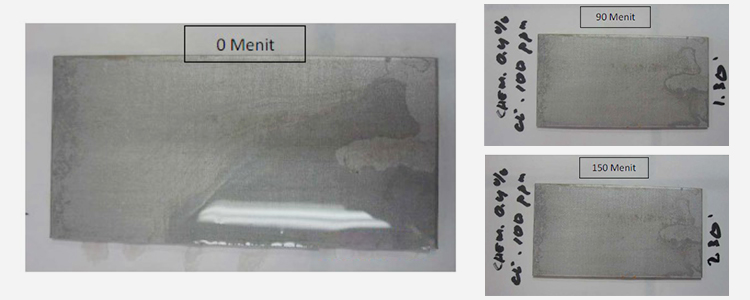

Resistance of StopMark W205 0.5% against HCL 100 ppm contaminants

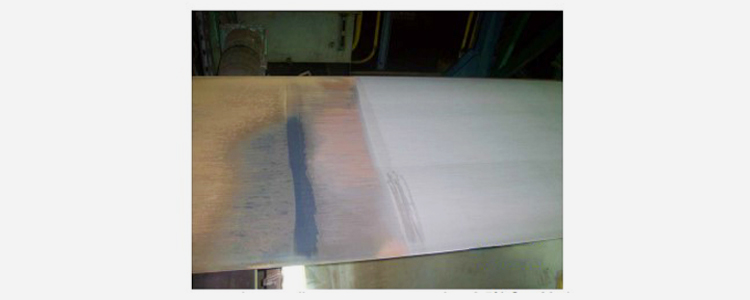

Comparison without & with 0.5% StopMark W205

Consult with EON Now

We are ready to listen and provide the right chemical solution for you. Consultation with our experts is free!

Home

Home