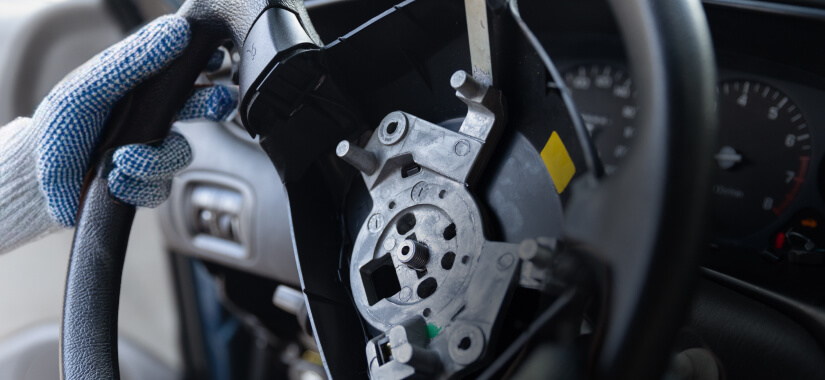

The steering assembly in the automotive industry is the process of assembling the steering system, which allows the driver to direct the vehicle with precision and good control. This process includes the installation of key components such as the steering wheel, steering shaft, rack and pinion, or other steering systems.

Each part must be installed with precision to ensure that the movement of the steering wheel is accurately translated into the movement of the front wheels. Proper assembly ensures that the steering system functions smoothly and responsively, providing optimal comfort and safety for the driver while meeting stringent quality standards.

Next, please review the common problems found in steering assembly and Eonchemicals solutions below.

1. Problem: Shaft Bearing Not Resistant to High Rotation

This issue can be caused by the design or material of the bearing being inadequate to withstand high loads and rotational speeds, which can occur during vehicle operation.

Another cause is the use of improper lubricants that do not meet quality standards, thus failing to perform at high rotations. When the bearing cannot withstand high rotations, it can lead to increased friction and heat, which can subsequently result in wear, deformation, or even total bearing failure.

Solution: Molykote BG 20

Molykote BG 20 is suitable for addressing the issue of shaft bearings that are not resistant to high rotations because this lubricant is specifically designed for applications requiring resistance to high speeds and loads.

Molykote BG 20 has superior thermal stability and the ability to maintain its viscosity and performance at high temperatures and rotations, thus reducing friction and heat generated.

Additionally, this lubricant has strong anti-wear properties, which help prevent wear, deformation, and total bearing failure. By using Molykote BG 20, shaft bearings can operate more efficiently and reliably, extending their service life and enhancing the overall performance of the vehicle.

2. Problem: Speedometer Rust and Moisture

Issues with the speedometer in the steering assembly of the automotive industry often involve rust and moisture. Rust can occur on the internal components of the speedometer due to exposure to moisture or condensation, especially if there is a leak or imperfect seal.

Moisture entering the speedometer unit can cause corrosion on metal parts and damage to electronic circuits, resulting in inaccurate speed readings or even total speedometer failure.

Solution: Dowsil 3-1953

This is a conformal coating, a single-component, translucent, fast-drying with moisture RTV, with heat acceleration, soft, stress-relieving, containing a UV indicator.

This elastomeric conformal coating is suitable for the automotive and lighting industries that require various reliability standards as a coating for circuit boards, sensitive components, and fine-pitch designs.

It contains no additional solvents, dries at room temperature, and does not require an oven. This product has good adhesion to many substrates. The UV indicator allows for automatic inspection. DOWSIL 3-1953 has a UL 94 V-0 flame resistance rating and is recognized by UL 746E / UL746C.

3. Problem: Headlamp Leakage and Incompatibility

Common problems with headlamps in the steering assembly of the automotive industry include leakage and incompatibility. Leakage can occur due to ineffective seals or damage to the headlamp casing, allowing water or moisture to enter the lamp.

Incompatibility can happen when the selected headlamp does not match the vehicle’s design or specifications. Both issues can disrupt the main function of the headlamp and affect the driver’s safety and comfort.

Solution: Molykote EM 50 L

Molykote EM 50 L can be a solution to address leakage and incompatibility issues with headlamps in the steering assembly of the automotive industry because it is designed to provide protection against external elements.

Molykote EM 50 L has water and weather resistance properties, which help maintain the integrity of the seal and prevent moisture from entering the headlamp. Additionally, this product has high compatibility with various materials, allowing it to be used in various headlamp designs and specifications without causing damage or incompatibility.

Please contact us for the best advice and recommendations according to your needs in the field.

| Read automotive industry utilities problems and solutions

4. Problem: Plastic Material Leakage

Leakage in plastic materials can occur due to various factors, such as improper manufacturing processes, the use of materials unsuitable for the operational environment, or damage to the plastic components themselves.

This leakage can result in issues such as the loss of hydraulic fluid or lubricant, which in turn can disrupt the steering system’s functionality, such as driver responsiveness or component reliability.

Solution: Dowsil RTV

Functions as a sealant to add mechanical stability to individual components. This product is non-flowing and has enhanced thermal stability.

| Read also tie rod assembly problems and solutions

Its application does not require mixing, can dry at room temperature, and does not require an oven. Please contact us for additional information.

Consult with EON Now

We are ready to listen and provide the right chemical solution for you. Consultation with our experts is free!

Home

Home