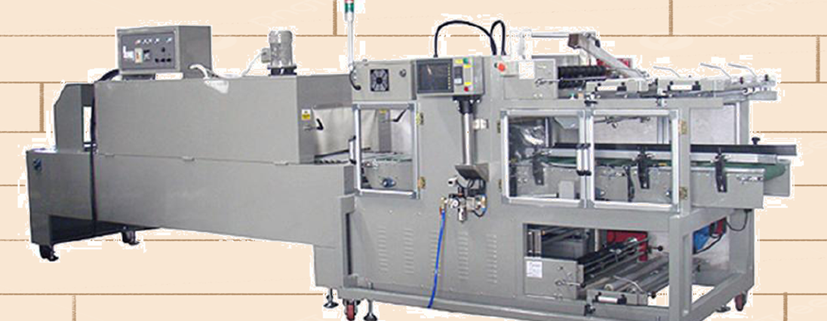

The shrink labelling system in the beverage industry is a system used to apply shrink labels to bottles or beverage packaging. This process involves using plastic labels that are stretched and heated to adhere tightly to the bottle or packaging, creating a neat and attractive appearance.

The wrapping packaging machine is a machine used to wrap or coat beverage packaging with protective materials, such as plastic or paper. This machine can quickly and efficiently wrap packaging in the form of bottles, cans, or other types of packaging, providing additional protection and enhancing product presentation.

Some problems and solutions for these machines are as follows:

1. Problem: Glue Residue on Labelling Machine

This problem occurs when remnants of glue or residue from previous labels stick or settle on parts of the labelling machine. This can be caused by using inappropriate glue or a lack of proper maintenance on the machine. Glue residue can disrupt machine performance, causing labels to be poorly printed or not adhere properly, and can even damage machine components if not cleaned correctly.

Solution: EonSolv 135

EonSolv 135 is a general cleaning degreaser, a clear (colorless) cleaner. This product is ideal for general maintenance cleaning in the food and beverage industry, automotive industry, maritime, and transportation equipment.

EonSolv 135 can remove grease, glue, lubricating oil, rust inhibitors, and other contaminants from metal surfaces and other materials. Besides cleaning, this product also protects and extends the life of equipment with its simple and easy application. However, it is not recommended for use on materials sensitive to aliphatic hydrocarbon compounds like rubber.

Features and Benefits of EonSolv 135

- Quickly cleans contaminants

- Economical cleaner

- Higher flash point than room temperature, hence non-flammable at room temperature

- Does not cause rust and is safe for use on all types of metals

- Leaves no residue, eliminating the need for rinsing with water after application.

Please chat with us on WhatsApp for more information.

2. Problem: Grease/Oil on Chain Contaminating Products

Lubricant contamination occurs when the lubricant melts or is unsuitable for fast-moving chains. This can damage products, cause recalls, pose health risks, reduce trust, and lead to financial losses for the company.

Solution: Molykote AFC Series

Molykote AFC is the solution to grease/oil problems on chains contaminating products for several reasons:

- Heat-resistant

The heat-resistant formulation prevents the lubricant from melting and detaching from the chain into the production area. - High speed

Suitable for fast-moving parts, providing optimal lubrication without the risk of contamination. - Stable

High stability ensures consistent lubrication performance under various operational conditions. - Efficient

Reduces maintenance frequency and downtime, increasing operational efficiency and reducing maintenance costs

Eonchemicals is the official distributor of Molykote in Indonesia, guaranteeing quality and authenticity, with lubrication experts ready to assist you.

Please chat with us on WhatsApp for a free consultation or more information about Molykote AFC lubricants.

3. Problem: Short Regreasing Interval

Another term for the regreasing interval is the regreasing period, which is the time interval for reapplying grease. A short regreasing interval results in excessive grease consumption. Additionally, more labor and time are required for the task.

Do not buy cheap grease with short regreasing intervals as it becomes more wasteful and increases costs.

Solution: LE Lubricant Series

LE Lubricant is the solution to short regreasing intervals because:

- Specially formulated for longer endurance, thus extending the regreasing interval

- International quality lubricants, excellent in reducing wear

- Capable of withstanding contamination from water, dust, and chemicals, thus extending the relubrication period

- Stable under various operational temperatures, thereby extending the regreasing interval

- Extending the regreasing interval reduces operational costs and downtime, and increases overall efficiency

- Extends the machine’s lifespan

| Read bottle washing problems and solutions on this site

Contact us via WhatsApp for more detailed information about Eonchemicals’ solution products.

Consult with EON Now

We are ready to listen and provide the right chemical solution for you. Consultation with our experts is free!

Home

Home