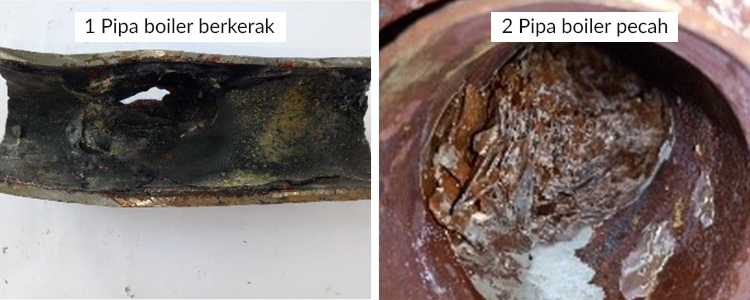

Boilers have a high potential for corrosion and scaling issues, which can reduce factory productivity and even cause significant financial losses for your company. Problems that can occur with boilers include:

Crusty boiler pipes Boiler pipe burst

Crusty superheater pipe Superheater pipe burst

Rusted boiler pipes

Without an appropriate treatment program, these issues can become a burden and risk for your factory operations.

Solutions for controlling corrosion and scaling:

- Maintaining feed water quality

It is important to limit the amount of impurities that enter the boiler - Internal chemical treatment program

This includes the type and dosage of chemicals to be applied based on the boiler’s operating pressure - Blowdown based on the cycle of concentration

It is crucial to maintain the concentration of dissolved solids and remove deposits resulting from chemical reactions in the boiler.

Eonchemicals offers a comprehensive protection program to control corrosion and scaling, which includes :

-

- Free-of-charge service, consisting of:

- Assessment

- Operator training

- Service monitoring

- Free-of-charge service, consisting of:

Please contact us for solutions to control corrosion and scaling in your boiler.

SUCCESS STORY

One of the palm oil companies in Indonesia found scaling and corrosion on the pipes, steam drum, and mud drum during an annual boiler inspection. If this problem is not properly addressed, it could be detrimental to the company.

SOLUTION

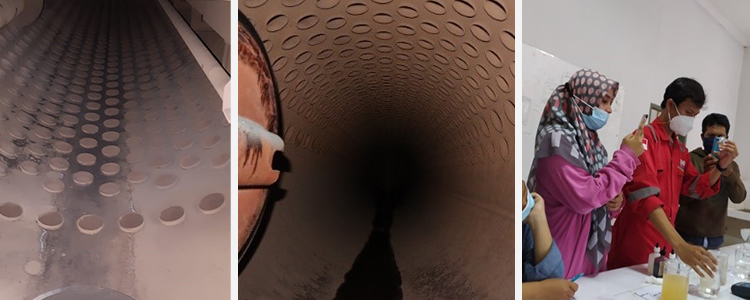

Eonchemicals conducted an XRF analysis on the scale samples and identified the issues based on daily laboratory water analysis data. Subsequently, the following solutions were provided:

- Chemical treatment

- Technical services including assessment, monitoring, operator training, and water analysi

The success parameters are:

- Boiler water quality meets standards based on the boiler’s operating pressure

- No corrosion and scaling in the boiler

RESULTS

The boiler inspection results after one year showed no corrosion or scaling in the boiler.

With the successful implementation of Eonchemicals’ chemical treatment and technical services program, the customer achieved several benefits and cost savings as follows:

| Benefit | Saving Cost |

| No offline boiler cleaning required | Rp 300.000.000/tahun |

| Reduced boiler pipe purchase costs | Rp 100.000.000/tahun |

| No unplanned shutdowns | Rp 500.000.000/tahun |

Consult with EON Now

We are ready to listen and provide the right chemical solution for you. Consultation with our experts is free!

Home

Home