Maximizing feedwater quality monitoring to prevent scale

Scale can lead to decreased boiler efficiency, and without an appropriate scale control solution, it can cause pipe failure due to overheating. The impact of decreased boiler efficiency is excessive fuel consumption to meet steam targets.

We offer a comprehensive chemical inhibitor program (phosphate, phosphate-polymer program) including routine monitoring (free of charge). We can collaborate with you on your scale control needs. Whether you are looking for solutions to optimize chemical costs, improve softener resin efficiency, demineralization plant, or reverse osmosis, EON can provide training on feedwater treatment unit maintenance and chemical dosage optimization to help you control scale in the boiler, thereby maximizing boiler efficiency.

Proper Scale Control – Reducing Chemical Costs

Scale control is one of the most common issues in every palm oil mill. Boiler operation requires a large amount of water every hour, and the number of impurities (e.g., hardness) in the feedwater can pose a serious threat to the boiler. Many operators use chemical scale inhibitors to suppress scale potential. However, this method is largely ineffective, as chemical consumption is too high, and the number of impurities is not balanced with the amount of chemical.

EON maximizes feedwater quality by offering routine monitoring solutions (free of charge), resin assessment in softener units, demineralization plants, and optimization of chemical scale inhibitor dosages. We have extensive experience in feedwater quality monitoring services to achieve efficient chemical costs.

Contact us to resolve your field issues

.

Internal Boiler Chemical Program

We have research and development, and reliable technical capabilities. We are committed to providing the best solutions and services to meet your field needs.

Benefits of using EON’s internal chemical program :

1. EON guarantees boiler freedom from issues. *according to SOP

2. Monthly routine monitoring

3. Diagnosis of potential issues based on water analysis results

4. Providing recommendations

5. Troubleshooting if issues arise

6. Supervision of corrective actions

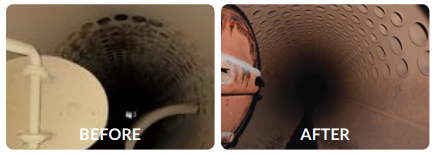

Success Story

One palm oil mill company experienced increased chemical costs and scale issues. The water treatment cost was IDR 1,256/m3, with a boiler capacity of 30 tons/hour. The company switched to EON for solutions that helped reduce chemical costs and scale issues. EON conducted intensive monitoring services to improve feedwater quality, which successfully reduced water treatment costs to IDR 753/m3 and minimized scale potential.

Download Success Story

Consult with EON Now

We are ready to listen and provide the right chemical solution for you. Consultation with our experts is free!

Home

Home