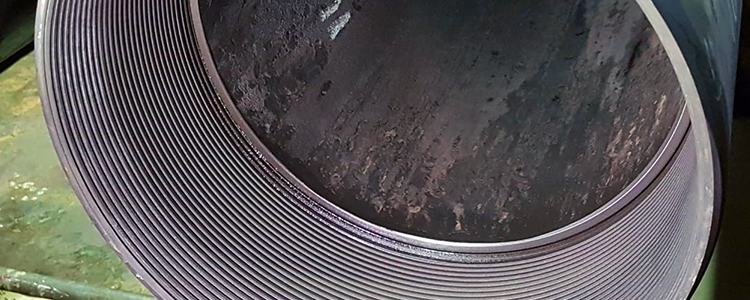

In addition to thread defects during the production process, thread corrosion is also one of the main reasons pipes are rejected during inspection. The threaded section of the pipe is highly susceptible to corrosion because it undergoes the most friction during the threading process. This corrosion is exacerbated by the duration and environmental conditions during storage, making it essential to manage the threaded section of the pipe properly.

Pipe Threads and Joints

Solution

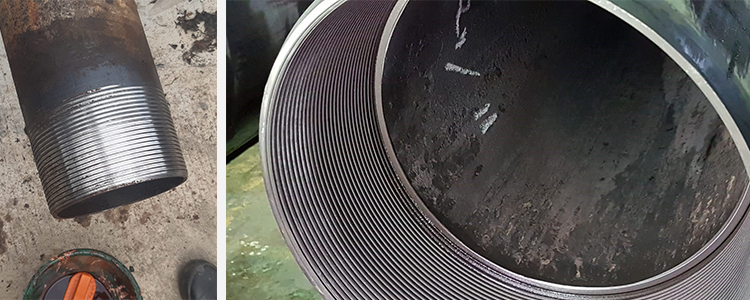

To address this issue, use an appropriate anti-rust coating that is easy to clean when the pipe is eventually used.

Application of Anti-Rust Coating on Threads and Installation of Thread Protectors

Success Story

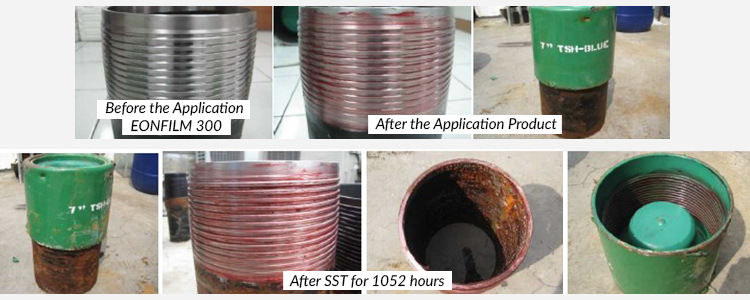

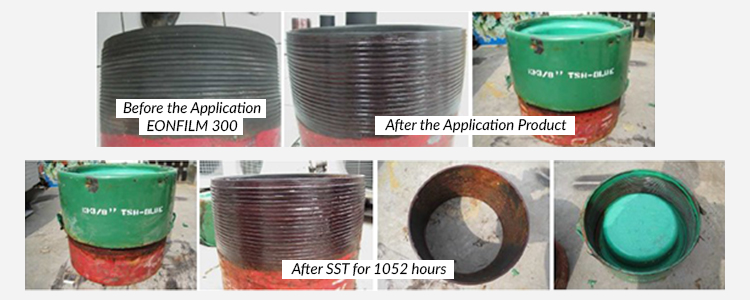

EonFilm 300 is a specialized product designed to provide strong and long-lasting anti-rust protection for pipe threads during storage. EonFilm 300 does not dry out, is easy to clean, and has water-repellent properties, ensuring the threads are well-protected from corrosion.

Many pipe and oil and gas companies have already adopted this product due to its recognized rust protection quality.

In Salt Spraying Test (SST) results over 1052 hours, EonFilm 300 successfully prevented corrosion from appearing on pipe threads.

SST Results of EonFilm 300 on 7-inch Pipe Threads

SST Results of EonFilm 300 on 13 3/8-inch Pipe Threads

For consultation on pipe and thread protection, please contact us.

Consult with EON Now

We are ready to listen and provide the right chemical solution for you. Consultation with our experts is free!

Home

Home