The washing process in the automotive industry aims to remove residual oil and coolant before further processing. Generally, the chemicals used for washing are water-based due to their cost-effectiveness.

While water-based cleaners have their advantages, they also present certain problems or challenges that must be addressed, such as:

- Fast washing cycle time, necessitating a cleaner with robust cleaning power in a very short time

- Cleaning a large number of parts

- Susceptibility to rust, as they are diluted with water

Therefore, the main issue in the washing process is the rejection of parts (due to rust or remaining dirt).

Solution

Considering these challenges, the appropriate solution is to use a chemical cleaner that works quickly, has strong cleaning power, and contains anti-rust properties.

Success Story

One automotive company faced rust issues that emerged after the washing process. The rusted parts required rework, resulting in additional costs and time.

Eonchemicals conducted a detailed investigation of the problem with the following findings:

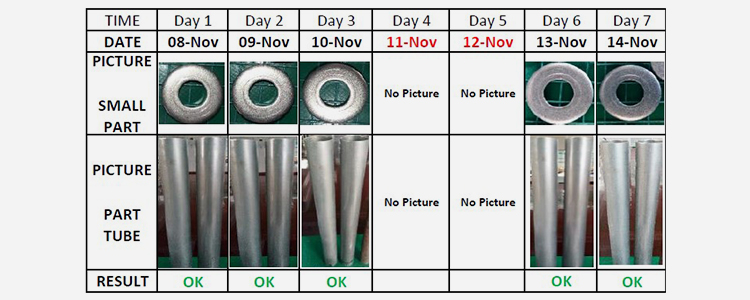

- Rust appeared 2 days after washing, while the requirement was rust-free for 5 days

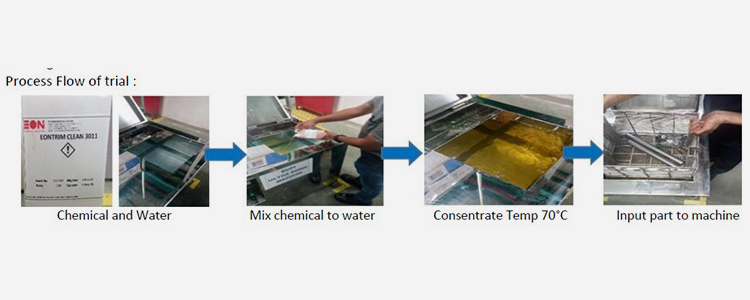

- The application used ultrasonic cleaning at 70°C for 7 minutes per part

- The predominant material was iron

Based on field data, Eonchemicals provided the solution product EonTrim Clean 3011, which has the following features and benefits:

- Contains anti-rust agents for short-term protection (transit)

- Versatile application, suitable for both immersion and spray

- Suitable for iron materials

- Effective and low-foaming

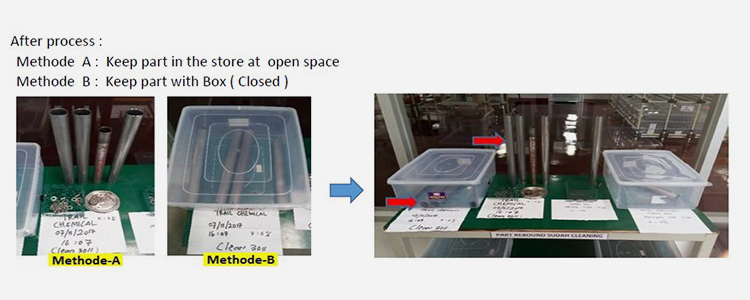

Trial Procedure

Conclusion

Choosing the right cleaner according to process needs can help make work more productive with more economical costs and can address rejection issues due to washing failures.

Contact us immediately for a free consultation regarding improvement programs and production cost reduction.

Consult with EON Now

We are ready to listen and provide the right chemical solution for you. Consultation with our experts is free!

Home

Home