One of the renowned motorcycle manufacturers is facing a problem in the honing process. NG/Reject in the form of scratches is often found on the Cylinder Compression Head component, which is made of 70% ferrous and 30% aluminum materials. From the discussions and genba sessions with the engineering team, we obtained the following data:

- Scratches frequently occur on aluminum material.

- The coolant used is neat oil, leaving some residual chips on the tools.

- The chips or sludge produced are very fine.

- Sludge from the process is cleaned once a month.

- The coolant’s lifespan is 3 months before it starts to smell.

- The process speed is categorized as moderate, as high precision results are required

Solusi

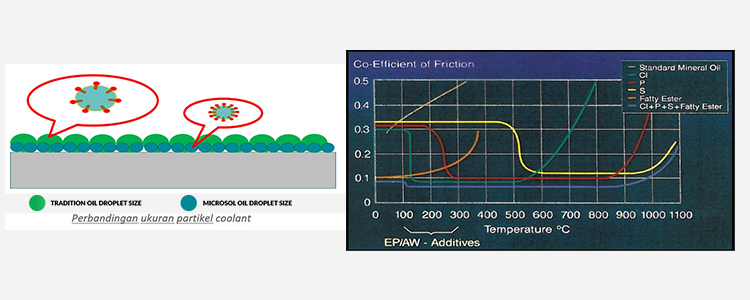

We proposed a trial of the EONTRIM MS690XT product. This coolant has micro-sized particles, enabling maximum reach into small gaps during the machining process.

This capability is particularly suitable for the honing process, where the roughness results are measured in microns.

Features and benefits of EONTRIM MS690XT:

- Water-soluble coolant with very small (micro) particle size, ensuring maximum penetration into cutting areas.

- Compatible with various types of metals, both ferrous and non-ferrous.

- Contains EP additive to prevent chips/residues from sticking to tools or parts.

- Contains anti-rust agents that form a thin film to prevent rust on machines and are non-sticky

The customer agreed to conduct a trial in the honing process. Based on the technical meeting, the trial will be conducted for 3 months to observe performance and an additional 1 month to assess the durability of the EONTRIM MS690XT coolant.

Results

After a 4-month trial, several improvements were observed, including :

| Parameter | Existing | EonTrim MS690XT |

|---|---|---|

| Coolant Type | Neat Oil | Micro Emulsion |

| Coolant concentration | 100% | 5-7%/td> |

| Surface Finished | Defect rate > 10% | No Defect |

| Consumption/machine/month | 120 L | 24 L |

| Machine Cleaning | Every 1 month | Every 3 months |

| Improvement tool life | 50% | |

PT EONCHEMICALS PUTRA also recommends a filtration treatment to remove accumulated sludge at the bottom of the tank every 3 months (free service) to extend the coolant’s lifespan and periodically clean the machine.

Conclusion

EONTRIM MS690XT not only eliminates the scratch problem on parts but also provides improvements in tool life, coolant consumption, and coolant lifespan, directly impacting coolant waste disposal costs.

If you have the same problem or other problems regarding coolant, anti-rust or cleaner in your production process, do not hesitate to contact us because we can provide a free consultation.

Consult with EON Now

We are ready to listen and provide the right chemical solution for you. Consultation with our experts is free!

Home

Home