There are several issues that often occur during the steel coating process due to inadequate cleaning, one of which is uncoated areas. Uncoated surfaces on the strip can be detrimental to the company as the product’s market value decreases. If this problem cannot be resolved, it will certainly be very disadvantageous for the company.

To avoid these issues, several methods are employed to ensure the cleaning process works optimally, one of which is using steam/hot cleaning.

Using steam can facilitate the cleaning process, as rolling oil and other contaminants on the strip surface become easier to remove. However, production costs increase significantly because a substantial amount of gas is needed to produce steam.

One customer spends approximately Rp 66 million per week for steam production.

Unbeknownst to the customer, this is a problem! Why? Because fundamentally, high production costs will affect the product’s selling price. Nowadays, many companies are striving to reduce production costs so that their products can compete in the market.

Solution

The right solution to address this issue is to use EonElectrol 300, an alkaline chemical cleaner that can clean the strip surface of rolling oil and other contaminants during the cleaning process without the need for steam. This method is very practical and can save production costs while maintaining good quality results.

EonElectrol 300 is a steel plate cleaner that does not require steam or high process temperatures. It has excellent cleaning power at room temperature, 25 degrees Celsius. Rinsing can be done at room temperature up to 60 degrees Celsius, depending on field conditions.

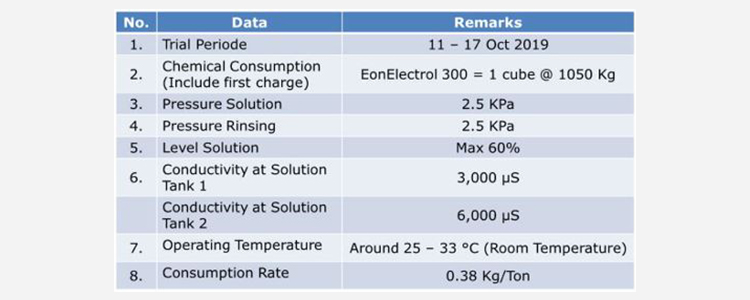

A trial at one customer site lasted for 7 days with very satisfying results. It was conducted on the MCL 1 machine at temperatures ranging from 25 to 33 degrees Celsius. One tote tank can clean up to 2717.21 tons, with an estimated consumption of 0.38 kg/ton. The detailed conditions of the alkaline cleaner trial can be seen in the table.

The quality of the finished goods also improved, with 96.51% prime product (high-value) from 2717.21 tons.

Referring to the steam consumption calculation scheme, using the alkaline cleaning product EonElectrol 300 can save costs up to Rp 266,000,000 per month.

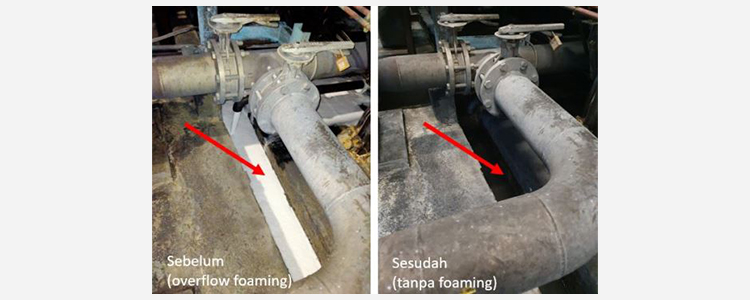

As operational costs decrease and the cleaning process becomes easier, the issue of overflow foaming can also be resolved. Thus, the alkaline cleaner EonElectrol 300 is a solution product that can address several problems simultaneously.

For further consultation about cleaning chemicals with alkaline cleaners or other types, please chat with us.

Consult with EON Now

We are ready to listen and provide the right chemical solution for you. Consultation with our experts is free!

Home

Home