The brake drum (drum brake) is a crucial component of a vehicle’s braking system. This part creates friction with the brake pads to stop or slow down the vehicle. The manufacturing process of brake drums includes turning, milling, and reaming. What are the issues, and how can they be resolved?

Several issues can be found in the brake drum manufacturing process, including:

- A significant amount of coolant carried off by the process chips

- Excessive coolant waste

- High coolant consumption, leading to inefficiency

- High production costs per part

All these issues are also a concern for a brake drum manufacturing company that is actively pursuing cost reduction. The company then entrusted Eonchemicals to address these problems.

Solution

After gathering sufficient data from the field, Eonchemicals recommended the metalworking fluid or metal coolant EonTrim SC310 to tackle the aforementioned issues.

Features and benefits of EonTrim SC310 :

- Semi-synthetic metal coolant compatible with various types of materials

- Contains EP Additive which acts as a lubricant and prevents chips from sticking to parts and tools

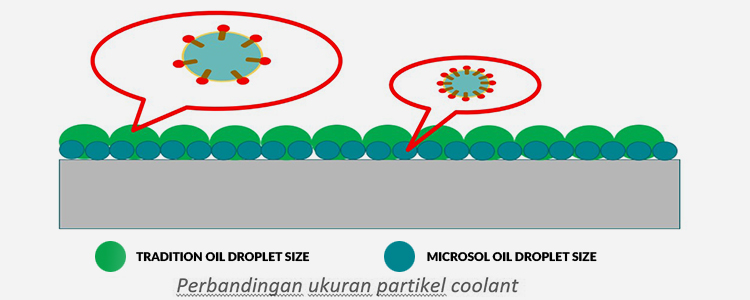

- Has small particle size (micro), ensuring better penetration and significantly reducing the amount of coolant carried off by process chips or workpieces

Trial Results

During a 1-month trial period, the following data were obtained:

| Parameter | Parameter | EonTrim SC310 | Saving |

| Chips moisture content (%) | 7.2 | 2.6 | 64% |

| Konsumsi coolant /part (ml) | 1.5 | 0.9 | 40% |

| Cost/part (Rp/kg) | 140 | 100 | 29% |

The data shows that using EonTrim SC310 can reduce carry off by up to 64%, lower coolant consumption by 40%, and save cost per part by 29%.

Additionally, the use of EonTrim SC310 can also reduce waste due to its longer lifetime, extending to 6 months from the previous 3 months.

Conclusion

Choosing the right coolant has proven to help reduce coolant consumption, save cost per part, minimize carry off, and decrease waste.

For a free consultation on coolant or metalworking fluid for cost reduction and efficiency programs in your company, please contact us.

Consult with EON Now

We are ready to listen and provide the right chemical solution for you. Consultation with our experts is free!

Home

Home