As one of the main components in an engine, the piston is designed in such a way that it can withstand the explosive forces resulting from combustion and perform translational movements smoothly. The friction that occurs between the piston and its cylinder causes damage to the piston, as shown in the image below.

Example of piston damage due to friction

Example of piston damage due to friction

Solution

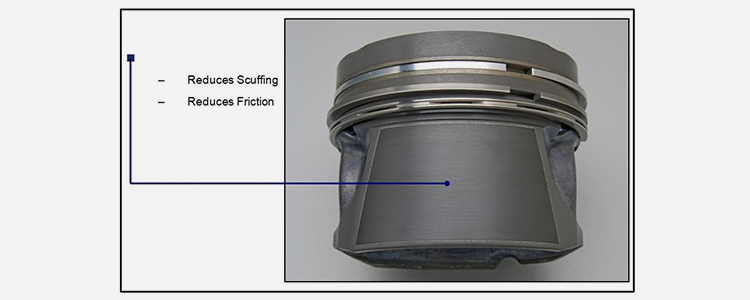

To prevent such issues, the friction between the piston and its pathway must be minimized. By reducing friction, excessive heat and wear can be prevented. One of the latest technologies to reduce this friction is by applying a dry lubricant coating on the piston, known as piston skirt coating.Case Study

Eonchemicals offers a solution with the Molykote Anti Friction Coating (AFC) PA-744 dry lubricant, which is applied as a piston skirt coating. Molykote AFC PA-744 is classified as a high-temperature resistant lubricant because its working temperature range is from -75°C to 300°C. It can be applied for heavy loads and effectively prevents wear.

There are two methods to apply the Molykote AFC PA-744 solid lubricant or dry film lubricant on the piston:

- Screen printing

Applying the solid lubricant layer on the piston by printing it similarly to screen printing. - Spray coat

Applying the solid lubricant layer on the piston by spraying the lubricant mist with pressurized air.

Success Story

Molykote AFC PA-744 can provide protection to the piston skirt by minimizing friction over a long period, making the piston skirt more durable.

For a free consultation, please chat by clicking the WhatsApp button below.

Consult with EON Now

We are ready to listen and provide the right chemical solution for you. Consultation with our experts is free!

Home

Home