OCTG pipe connections generally use dope (pipe cap) and thread compound (lubricant for pipe threads). The oil and gas industry typically uses API modified thread compound, which contains 60% of a combination of Lead, Fe, and Copper.

Pipes that use dope and compound during storage face the following problems:

- Unstable torque during running-in

- The compound contains heavy metal elements (Lead, Fe, and Copper) that can lead to environmental pollution

- The dope must be removed and cleaned before use

- Generates hazardous waste from compound cleaning

Solution

To address the above issues, Eonchemicals offers a solution with a dry lubricant, namely anti-friction coating (AFC), which is applied to OCTG pipe connections. By using this AFC product, dope and compound are no longer needed. Other benefits include:

- Stable torque

- Cleaner environment

- More practical, as there is no need for compound cleaning or dope removal

- Does not generate hazardous waste

Success Story

Based on the application results, the use of dry lubricant Anti Friction Coating (AFC) as a premium connection technology in extreme environments has proven successful. Several tests, such as the following, have been conducted:

- Salt Spray Test (SST)

The ASTM B117 standard evaluation was conducted to determine corrosion resistance by spraying salt; AFC has proven to withstand this test.

Salt Spray Test

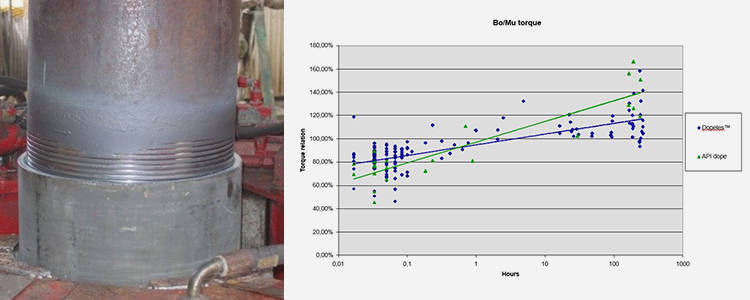

- Torque

With AFC application, torque values are more stable compared to conventional methods (see table below)

Conclusion:

- Anti Friction Coating (AFC) dry lubricant as a premium connection technology is used to replace thread compound and dope.

- It has been proven to provide stable torque, rust resistance, and environmental friendliness

Contact us for a free consultation before proceeding with the coating process on your pipes.

Consult with EON Now

We are ready to listen and provide the right chemical solution for you. Consultation with our experts is free!

Home

Home