n the steel industry, defects on coil sheets due to pin point rust problems result in a decrease in the coil’s market value. Pin point rust generally occurs due to long waiting times for the reoiling process at the finishing line and high relative humidity (RH>60%) in storage.

Solution

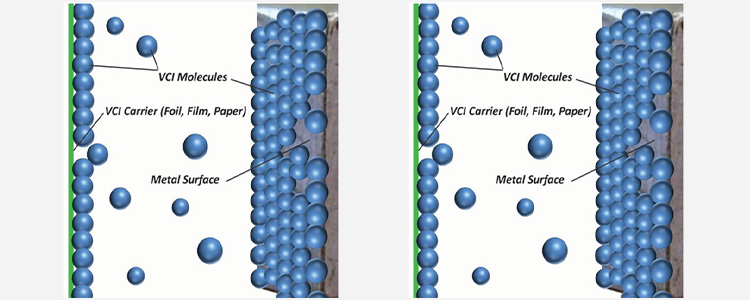

Eonchemicals has developed a wet temper fluid product called Roll Klin 250, which uses vapor corrosion inhibitor (VCI) technology that works as follows:

- The VCI additive evaporates and covers the entire metal surface

- Forms a layer to prevent oxidation

- The layer is hydrophobic, preventing high air humidity from adhering to the metal

Corrosion Preventive Method

In addition to VCI technology, Roll Klin 250 contains a wetting agent to prevent carry over and wear on coil sheets. It is also equipped with a cleaning additive that functions to remove contaminants from the work roll.

Success Story

One of our customers in the steel industry initially often complained about pin point rust issues in their cold roll coil products. Eonchemicals was given the opportunity to provide a solution with the Roll Klin 250 product on their production line.

During the Roll Klin 250 trial, coil observations were conducted every 2 days over a period of 6 days. The observations showed no pin point rust, so the trial continued until the Roll Klin 250 stock was exhausted.

Observation Results of Roll Klin 250 Application

Conclusion

Roll Klin 250 is capable of providing a solution to pin point rust problems with satisfactory results, so the customer continues to use the product.

For a free detailed consultation about Roll Klin, please contact us..

Consult with EON Now

We are ready to listen and provide the right chemical solution for you. Consultation with our experts is free!

Home

Home