In the steel industry there is a pickling line for the process of cleaning the steel surface from impurities such as iron oxide and other impurities. This process is important to improve the quality and durability of the steel, as well as to prepare the steel for the next stage of processing such as coating or forging.

1. Problem: Over Pickle

This issue results in the thinning of the steel strip material due to the corrosive effect of hydrochloric acid used during the pickling process. It can further increase the risk of the steel strip breaking and can become an obstacle for subsequent processes.

Solution: EonCor W203, Acid Corrosion Inhibitor

Provides metal protection from hydrochloric acid (HCl) corrosion during the pickling process.

Features and Benefits of EonCor W203

- An effective acid inhibitor that can prevent over pickling

- Can be applied at high temperatures

- Stable in acidic conditions

- Non-foaming

Application Method

- Mix directly with concentrated acid (based on the volume of concentrated acid)

- The maximum concentration used is 0.1% of the volume of concentrated hydrochloric acid (HCl)

- Consult our experts to determine the best concentration for specific field cases

- If heating the acid or equipment is required, do so before cleaning

Please contact us for further information on acid corrosion inhibitors or to consult.

2. Problem: Stoppage Mark/Stain

This problem is caused by residual acid on the strip surface, making it look dirty and lowering the product grade, which ultimately reduces its selling price.

Solution: StopMark W205, Pickling Line Rinse Additive

An additive used primarily during the rinsing process in the pickling line of steel manufacturing..

Features and Benefits of StopMark W205

- Provides excellent stain/mark protection

- Excellent rinsing properties

- Low-foaming material

Application Method

- Prepare a 0.5–0.75% solution in a separate container

- Injection into the rinsing tank is not recommended

- When the pickling line stops, immediately use clean rinsing water on the strip for about 5 minutes

- Spray the prepared solution on the top and bottom of the strip (10–15 minutes)

- Reuse of the used solution is not recommended

- Protection against marks or stains is expected for at least 2 hours

3. Problem: Conventional Lubricants Dry Out Quickly

Lubricants that dry out quickly are ineffective and can even cause machinery to wear out faster due to inadequate lubrication.

Solution: Molykote BR2 Plus, Excellent Lubricating For Metal Friction

Molykote BR2 Plus lubricant is ideal for application on roller bearings, slide bearings, guides, roller guides, and as automotive chassis grease.

Features and Benefits of Molykote BR2 Plus

- Does not dry out easily

- High load-bearing capacity

- Longer lifespan, durable

- Excellent oxidation resistance

- Suitable for lubrication in hard-to-reach conditions, forming an oil film

- Reduces wear

- Good water resistance

- Protects against corrosion

Application Method

- Clean the material from all types of dirt

- Use on slide bearings, roller bearings, guides, roller guides, splines, ball joints, low-speed small gears, and also for automotive chassis lubrication

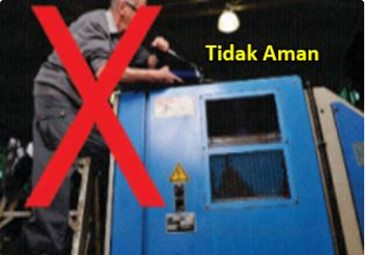

4. Problem: Hard-to-Reach and Hazardous Bearings

Several lubrication points are often found in high or narrow spaces, making them difficult for operators to reach. Bearings are sometimes located in extremely hot, noisy, or slippery areas, posing a danger.

Solution: EonLube 250, Autolubricator

Suitable for addressing lubrication points that are hard to reach, located in hazardous areas (heat, noise, electricity, etc.), and for machines that cannot be shut down during regreasing.

Features and Benefits of EonLube 250

- Automatic & multi-purpose lubrication

- Uses MLQ (Minimum Quantity Lubrication) software, making it more economical

- Automatically determines the ideal lubrication volume and interval

- Uses high-performance lubricants

| Read steel industry slitting problems and solutions

Application Method

Contact our expert team for the optimal installation of the automatic lubrication system.

Consult with EON Now

We are ready to listen and provide the right chemical solution for you. Consultation with our experts is free!

Home

Home