The extruder is the main tool in the extrusion process, which includes mixing, kneading, forming, and cooking materials. This machine is widely used in feed factories (animal feed & aquafeed). The lubricant used cannot be arbitrary. Common lubrication problems include:

- Frequent top-ups of grease because the grease is not suitable for heavy loads

- Bearing damage or bearing seizure

- Bearing temperature quickly rises above 50°C

Solusi

To address these issues, a grease with excellent load-bearing capacity is required. Use grease that contains the solid lubricant additive MoS2 (molybdenum disulfide). The solid lubricant in the grease can minimize friction, making the bearings last longer and extending the intervals between grease top-ups. Therefore, Eonchemicals presents Molykote BR2 Plus lubricant.

Success Story

One of our customers experienced high grease procurement costs, with the extruder machine conditions as follows:

- Regreasing every day with a manual grease pump

- Load: moderate

- Environment: slightly dusty

- Temperature: ± 100°C

- Speed: moderate (1400 rpm reduced to 600 rpm)

- Grease consumption: 1 pail/month (1 pail = 16 kg)

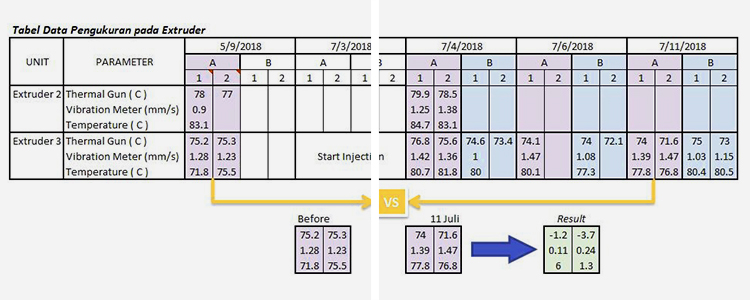

After using Molykote BR 2 Plus lubricant, the results were as follows:

Data recorded and field monitoring showed that Molykote BR2 Plus could perform well even without regreasing the bearings for a week, and no signs of damage appeared.

Total cost savings exceeded IDR 33 million per month.

For those of you who want to achieve cost savings on grease procurement with satisfactory performance results, please consult/chat by clicking the WhatsApp button below.

Consult with EON Now

We are ready to listen and provide the right chemical solution for you. Consultation with our experts is free!

Home

Home