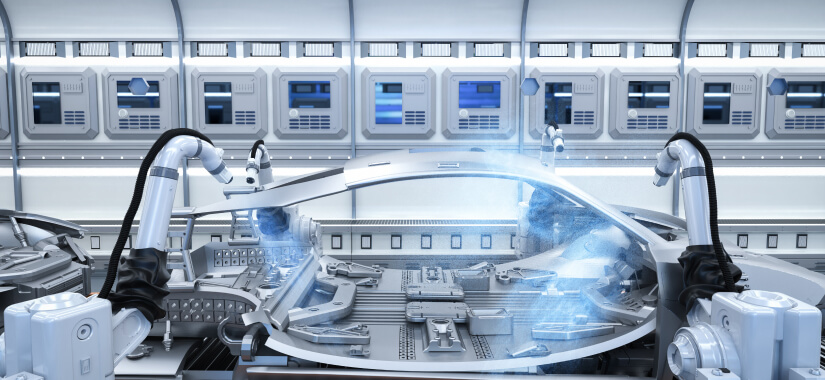

Painting in the automotive industry is a crucial process to provide finishing and protection to vehicle surfaces. This process begins with surface preparation, which includes rust removal, sanding, and primer application to enhance paint durability.

Next, the vehicle is painted with a base coat and a top coat chosen according to customer specifications and preferences. Afterward, a baking or drying process is carried out to strengthen the paint and achieve optimal gloss.

Aside from aesthetic aspects, painting also plays a significant role in protecting the vehicle from corrosion, extreme weather, and mechanical damage, thereby ensuring the vehicle’s beauty and longevity.

Common problems in this unit along with their solutions from Eonchemicals are as follows.

1. Problem with Belt Conveyor: Uncontrolled Grease Consumption

This issue is often caused by the negligence of workers in this unit or their inability to determine when regreasing is actually needed. It can also be due to the quality of the grease and unstable operations, resulting in inconsistent regreasing intervals.

Excessive grease consumption can lead to environmental pollution due to spills and increased grease procurement costs due to wastage

Solution: Autolube, Molykote BR2 Plus

Features and benefits of Autolube include:

- Automatic lubrication system

- Precisely and consistently regulates the amount of grease applied

- Reduces the risk of overuse

- Ensures each part receives the necessary lubrication without wastage

Features and benefits of Molykote BR2 Plus:

- High-performance grease

- Good durability

- Strong adhesion properties

- Reduces the frequency of reapplication

- Grease consumption can be well controlled

- Reduces operational costs

- Minimizes potential environmental contamination from excessive grease spills

Please chat with us by clicking the WA icon for further information.

2. Problem with Painting Component: Heat-Resistant Grease

If the grease cannot withstand the heat generated by the intense painting process, it can result in the degradation of grease quality, which in turn can disrupt operations and affect the overall efficiency and reliability of the system.

This issue requires the selection of the right grease that can operate at high temperatures and under intense workloads in the painting production environment.

Solution: Molykote 1000

Molykote 1000 is a solid lubricant paste that is free of lead or nickel. This paste is highly suitable for high-temperature operations up to 650°C and provides corrosion protection.

| Read also power window assembly problems and solutions

This lubricant product can offer reliable lubrication and corrosion protection, which is crucial to ensuring optimal performance and longevity of components under high-temperature and heavy-load conditions.

Discuss painting problems in the automotive industry and their solutions with us via WhatsApp now!

Consult with EON Now

We are ready to listen and provide the right chemical solution for you. Consultation with our experts is free!

Home

Home