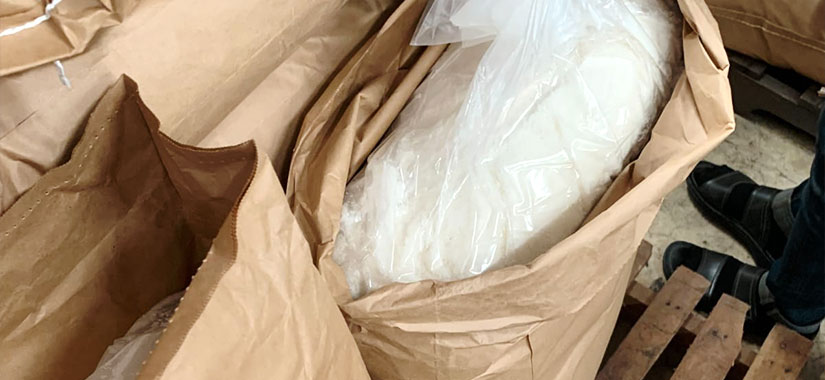

The packaging process for desiccated coconut aims to protect and maintain the quality of the product. Desiccated coconut is packed in various types of safe packaging.

The packaging also plays an important role in preserving the freshness of the product, maintaining its aroma, texture, and nutritional value over a specified period. The packaging process also involves the use of clear labels and product information to provide consumers with the necessary details.

Of course, this process encounters several problems. What are they? What are the solutions? Read the explanations below.

1. Problem: Ink Contamination on Printing Machine/Parts

First, a common issue is ink contamination on the printing machine or parts used in the packaging process for desiccated coconut. This contamination can occur due to accidental transfer of printing ink to the surface of the packaging or the machine. So, what is the solution?

Soluti0n: EonRollink 388

EonRollink 388 is a solvent-based cleaning solution designed to quickly and effectively clean oil-based inks. This cleaning chemical is suitable for use on UV printing machines and general printing machines, ensuring satisfactory cleaning results.

It is safe for routine use, as EonRollink 388 does not damage the rubber roll blankets on printing machines and does not cause rust on metal materials, keeping equipment in optimal condition.

For more information about EonRollink 388, you can chat via WhatsApp by clicking the available WA icon

2. Problem: Residual Glue Dirt on Labelling Machine

Another issue is the presence of residual glue dirt on the labelling machine used in the packaging process for desiccated coconut. This dirt can form due to leftover glue used to attach labels to the packaging, which can then dirty the labelling machine.

This condition not only affects the aesthetics of the packaging but can also impact the safety and cleanliness of the product. This problem can be addressed with EonSolv 135 as described below.

Solution: EonSolv 135

EonSolv 135 is a powerful general cleaning solution, including cleaning labelling machines dirty with glue, rust, grease, and other contaminants. Note that EonSolv 135 cleaning chemical is not recommended for use on rubber materials.

EonSolv 135 has a high flash point, so it does not ignite at room temperature. This product does not cause corrosion and is suitable for all types of metals. Additionally, EonSolv 135 does not leave any residue, so there is no need to rinse it off.

3. Problem: Grease/Oil on Chains Contaminating Products

This contamination typically occurs because the chain lubricant you use is a “wet lubricant” that drips and contaminates the product being processed.

The solution is, of course, to use Molykote AFC, a dry lubricant, so it does not drip onto your product.

Solution: Molykote AFC

The renowned specialty lubricant, Molykote AFC (Anti Friction Coating), is a type of dry lubricant. It is an effective solution to prevent lubricants from dripping and contaminating your product.

This dry lubricant has a formula that meets food safety and hygiene standards, making it safe for use in environments that process human consumption products. Molykote AFC offers long-lasting and stable lubrication for machine chains.

Make sure to try it! Contact us for satisfactory solutions and technical service.

| Read coconut water capping and packaging problems and solutions

4. Problem: Short Regreasing Intervals

Short regreasing intervals on equipment in the packaging process for desiccated coconut is an issue that should not be ignored. Short regreasing intervals indicate that the grease you are using is not suitable. It may not withstand the operational conditions at your company.

The grease may not be heat-resistant, may not withstand heavy loads, may not handle high speeds, or a combination of these factors. The right solution can be found below…

Solution: LE Lubricant

LE Lubricant is the right and effective solution to extend regreasing intervals. This specialty lubricant is designed with special technology that offers exceptional durability against high temperatures and harsh operational conditions, such as those often encountered in food production environments.

| Read pasteurised coconut milk problems and solutions

With the use of LE Lubricant, regreasing intervals can be extended due to its formulation that maintains optimal performance over a longer period.

Do not hesitate to discuss with us to find a better solution.

Consult with EON Now

We are ready to listen and provide the right chemical solution for you. Consultation with our experts is free!

Home

Home