The primary issue in the food and beverage industry is the use of lubricants that are not certified as food-grade, halal, and kosher, failing to meet food safety standards according to ISO 22000 regulations. Consequently, the products produced lack consumer trust.

Successfully selecting the appropriate lubricant can enhance equipment performance, reduce downtime, and lower total operational costs. Interested? This is the page you’ve been looking for.

Several pieces of equipment that require food-grade lubricants include:

- Mixers, ovens

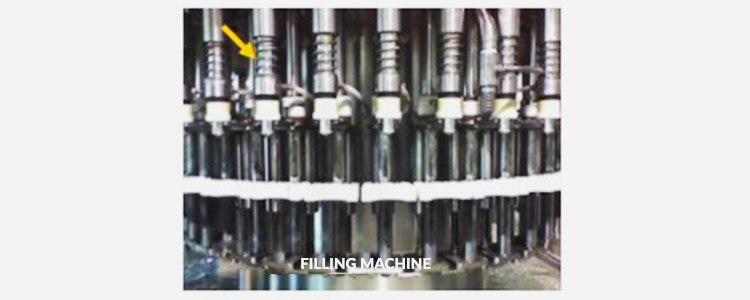

- Pumping & washing systems, filling & packaging, centralized lubrication systems, tank leak sealing

- Cutters, cooking chambers, conveyors

- Gearboxes, chains, valves

Companies that use the above equipment and need food-grade lubricants include:

- Bread, wafer, and candy manufacturers

- Dairy and beverage producers

- Processed meat producers

- Food packaging manufacturers

- Sugar mills

- Canned food producers, etc

Below are some examples of food and beverage industry equipment, their potential issues, and the appropriate type of food-grade lubricant.

Note: For optimal results, each type of equipment should use the most suitable type of lubricant.

Chains in the Ice Cream Industry

Potential problem: Continuous friction on the chains causes rapid wear, unplanned downtime, and production disruptions.

Solution

As a solution, Eonchemicals offers Molykote G-0051 FM Multipurpose (food-grade grease NSF H1 certified halal and kosher) to support ISO 22000. This grease is heat resistant (high-temperature grease) and performs exceptionally well in its class. It is resistant to water washout, safe for use on plastic and rubber, and suitable for application on gears, bearings, and chains in the food industry. Temperature range: -30 to 150°C, NLGI 1, mineral-based, aluminum complex thickener.

Consult an efficiency program for your business (free). Please Chat with us via WhatsApp now.

For easier application, use Molykote food-grade spray oil (NSF H1, temperature range -10 to 120°C, mineral-based, corrosion inhibitor, good penetration, odorless & tasteless).

Bearing in Rotary Sizing & Grading

Bearings in the rotary sizing & grading system are used for product transfer and sorting.

Potential problem: Bearings rust due to oxidation (hazardous to food).

Solution: Molykote G-0051 FM Multipurpose

NSF H1, temperature range -30 to 150°C, NLGI 1, mineral-based, aluminum complex thickener.

Molykote G-4500, Synthetic Multi Purpose Grease

Eonchemicals not only provides products (as a manufacturer) but also offers consultation, solutions, and technical services. Please: Chat with us via WhatsApp now for more information.

This is a synthetic food-grade grease product NSF H1 certified halal and kosher to support ISO 22000. It is a high-temperature resistant synthetic grease with excellent performance in its class, providing longer-lasting lubrication. Resistant to water washout, safe for use on plastic and rubber, and suitable for lubrication of gears, bearings, chains, pins, and many machine components in the food industry.

Chains & Bearings in Meat Processing

Potential problem: Chains exposed to humid conditions, lubricant contamination of meat.

Solution: Molykote G-0051FM, multipurpose

NSF H-1, halal, temperature range -30 to 150°C, NLGI 1, mineral-based, aluminum complex thickener. For easier application, use Molykote food-grade spray oil (NSF H-1, temperature range -10 to 120°C, mineral-based, corrosion inhibitor, good penetration, odorless & tasteless).

Mixers in the Food Industry

Mixing refers to combining wet and dry materials in the food industry. Mixers are used for mixing activities, commonly using paddle mixers because they are relatively compact and easy to clean.

Get the right lubrication solution for your business efficiency. Please CHAT WHATSAPP now.

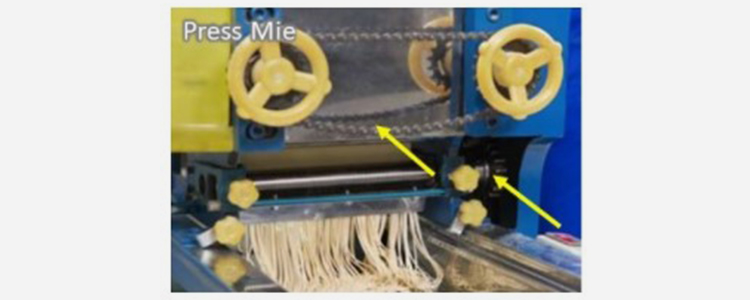

Chains & Gears in Noodle Press Machines

Potential problem: Liquid lubrication may contaminate the noodles being produced.

Solution: Molykote food-grade lubricant spray oil, easy application

NSF H-1, temperature range -10 to 120°C, mineral-based, corrosion inhibitor, good penetration, odorless & tasteless.

Gears in Noodle Press Machines

Potential problem: Gears operate continuously and are at risk of faster wear.

Solution: Molykote G-0051FM, multipurpose

NSF H-1, halal, kosher, temperature range -30 to 150°C, NLGI 1, mineral-based, aluminum complex thickener.

For more information or consultation about food-grade lubricants, please chat with us via WhatsApp.

Consult with EON Now

We are ready to listen and provide the right chemical solution for you. Consultation with our experts is free!

Home

Home