The mandrel uncoiler is one of the main machines used in the steel industry. It functions to hold or clamp the coil and uncoil the main coil into long sheet plates. Common problems encountered in the field include grease melting due to heavy loads, which results in:

- Short regreasing intervals

- High grease consumption

- Grease often dries out, leading to insufficient lubrication

- Frequent jamming or failure to expand

- Occurrence of stick-slip in the compartment

- If left unchecked, it can affect production outcome

Technical Data

The following are the technical data obtained from field observations:

Regreasing interval: Once per week

Load : 10 Tons / Coil

Environment : Dusty

Temperature : 50 degrees C

Speed : Slow

Solution

To address the aforementioned issues, Eonchemicals offers a solution with the product Molykote BR 2 Plus, a lubricant with the following characteristics:

Load : Medium to high

Environment : Dusty

Temperature : Covers up to 130 degrees C

Speed : Medium to high

Trial Results Over 1 Month

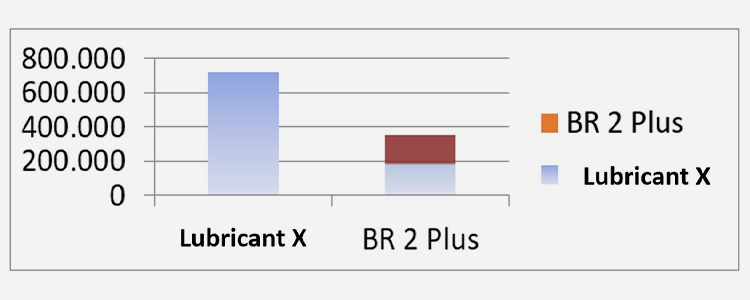

Based on a one-month trial, Molykote BR 2 Plus was able to deliver its best performance. The grease did not melt for 4 weeks, even under heavy loads of up to 10 Tons/Coil. The regreasing interval was extended from once a week to once every 4 weeks. Grease consumption decreased by up to 30% compared to the previous grease.

Conclusion :

Molykote BR 2 Plus provides a solution to the customer’s problems. It has excellent performance, extends regreasing intervals, and reduces operational costs.

For a free consultation regarding lubrication problems in your industry, please contact us.

Consult with EON Now

We are ready to listen and provide the right chemical solution for you. Consultation with our experts is free!

Home

Home