Hammer mills in the animal feed industry are used to break down materials into smaller pieces for further processing. Due to the heavy loads and high rotations, there are often issues with the grease used. Low-grade grease tends to leak out of the bearings, resulting in insufficient lubrication, overheating, and eventually bearing failure. This not only leads to excessive grease consumption but also shortens the bearing’s lifespan, driving maintenance costs sky-high.

Grease Melting Causes Bearing Damage

Solution

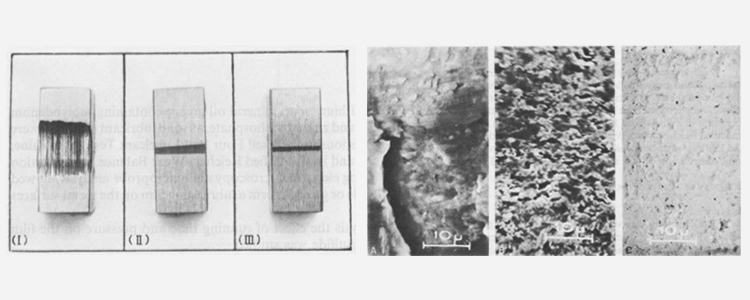

The appropriate lubricant for hammer mills should be capable of withstanding heavy loads, high rotations, and providing long-term lubrication. This includes lubricants containing solid lubricants (MoS2) and suitable thickeners. Below is a comparison of lubricants with MoS2 solid lubricant and those without it.

Wear Test with Lubricants on Block Tester and Micrographic Visualization

(I) Base oil

(II) Base oil +3% AW (anti wear)

(III) Base oil + 3 % MoS2 ( Molybdenum Disulfide Solid Lubricant )

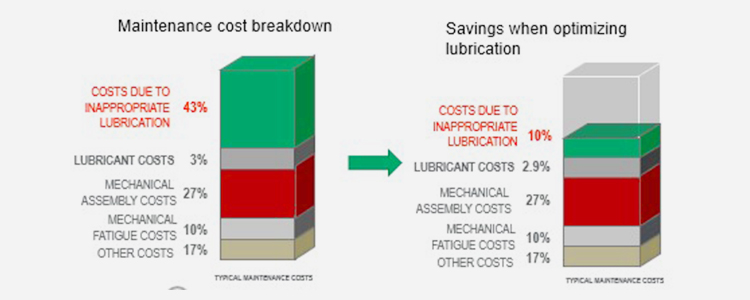

According to data from a study by IAME (Italian Association of Maintenance Engineers) & IRI (International Research Institute) in conjunction with SKF during the 1998 conference, the correct use of lubricants can reduce maintenance costs by up to 33%.

Success Story

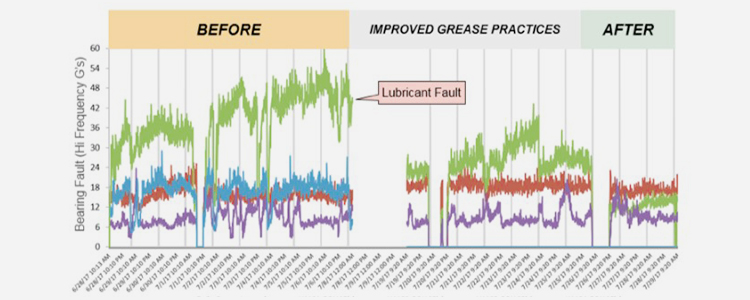

A customer in Magelang frequently experienced overheating issues with the hammer mill bearings, reaching temperatures of up to 80°C. The grease in the bearings would dry out within a week, necessitating disassembly and regreasing every week.

- Load : 25 ton / hour

- Environment : Indoor

- Temperatur : 35 C

- Speed : 1500 – 2000 rpm

To address this issue, Eonchemicals provided a solution with Molykote BR 2 Plus lubricant. This grease contains MoS2 (Molybdenum Disulfide) solid lubricant and a lithium complex thickener, making it suitable for bearings under heavy loads and high speeds. Molykote BR2 Plus is highly suitable for hammer mill bearings, offering long-term lubrication that prevents the grease from drying out quickly.

Here are the results and benefits after the customer in Magelang used Molykote BR 2 Plus:

- Regreasing interval: 1 month (previously 1 week)

- Grease lasts 1 month (previously dried out in 1 week)

- Bearing temperature: 50 – 60°C (previously up to 80°C)

- Usage savings: 40%

- Customer receives routine after-sales service, visits, and training knowledge sharing

For those looking to improve grease performance and reduce operational costs, please contact us.

Consult with EON Now

We are ready to listen and provide the right chemical solution for you. Consultation with our experts is free!

Home

Home