Pickling is a process of cleaning metal using hydrochloric acid to remove impurities, including rust. In the steel industry, the pickling process is an essential part that must be performed.

Strip Resulting from the Pickling Process

The issue is that in the steel industry, over-pickling (loss of strip weight due to excessive erosion by acid) often occurs. This problem can further lead to strip breakage, posing significant danger and hindering the production process.

Solution

Generally, the pickling process takes place at a temperature of 800°C, with the chemical reaction:

FeO + 2HCl –> FeCl2 + H2O

During the pickling process, it is undesirable for the iron in the strip to react with HCl. Therefore, an acid corrosion inhibitor needs to be added to protect the cleaned strip, preventing excessive erosion.

Success Story

Eonchemicals has developed a solution product in the form of an acid corrosion inhibitor formula, EonCor W203. This product has been proven successful and has a long history of being used by the largest steel industries in Indonesia.

EonCor W203 functions as an effective inhibitor to protect the strip from excessive erosion by HCl, thereby minimizing strip weight loss (% weight loss) after pickling.

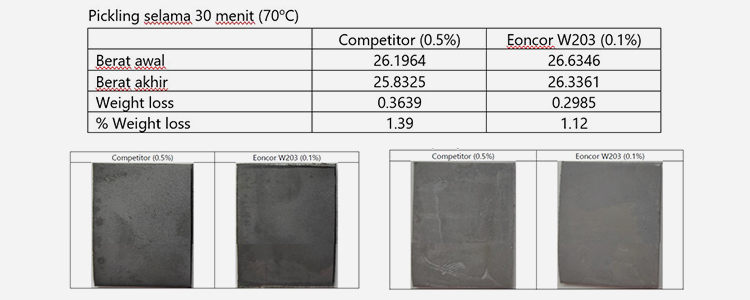

Below is the laboratory-scale comparison test data:

(a) Before Pickling (b) After Pickling

Comparison of pickling results

For free consultation on this problem or any other issues, please contact us.

Consult with EON Now

We are ready to listen and provide the right chemical solution for you. Consultation with our experts is free!

Home

Home