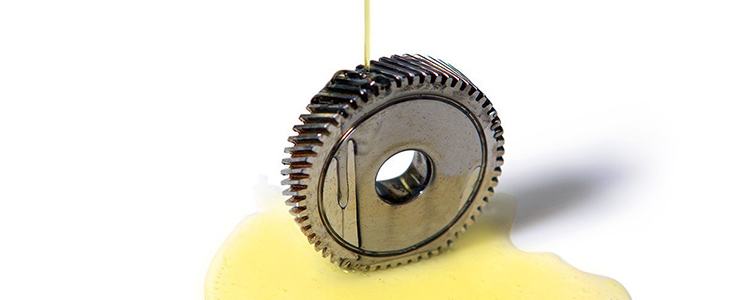

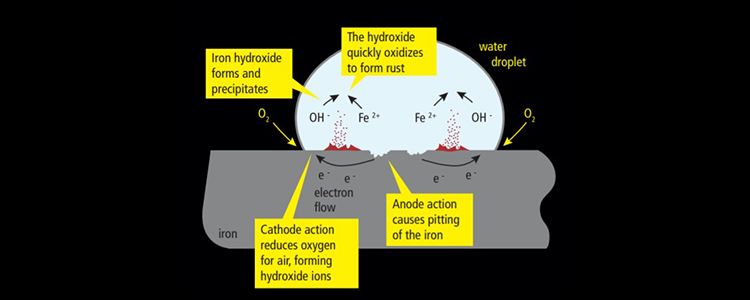

The presence of water residue from cutting or washing processes that gets trapped on parts diminishes the effectiveness of the anti-rust chemicals used. This issue causes parts to rust more quickly, failing to meet the intended protection plan. Rework processes are then necessary to remove the rust that has already formed on the metal surface. Naturally, this requires additional time and costs.

Solution

To address this problem, Eonchemicals, in collaboration with Master Fluid Solution – USA, has developed superior products to meet this challenge. Their innovation is the creation of anti-rust products that employ water displacing technology, which prevents water residue from being trapped during the application of the anti-rust treatment.

Success Story

One automotive component manufacturer experienced rust on parts after storing them for one month indoors, even though the anti-rust treatment used was supposed to provide protection for three months.

To solve this issue, Eonchemicals provided the EonTrim RPO6BF solution, which offers the following features and benefits:

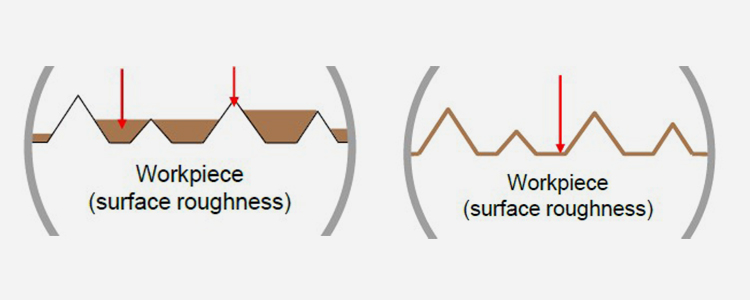

- Water displacing technology, capable of removing water residue from materials

- Barium-free

- Thin layer film, resulting in low carry-off

- Does not cause staining

- Prevents material oxidation during storage

Result

| Parameter | Existing | EONTRIM RPO6BF |

| Antirust type | Oil based | Oil based |

| Rust protection | 3 months | 6 months |

| Rust issue | >25% | No rust |

| Consumption month | 400 L | 300 L |

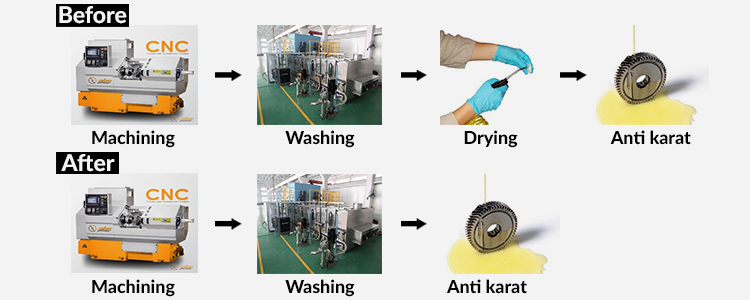

Improvement process

Conclusion

By using EonTrim RPO6BF, initially aimed at reducing the reject ratio due to rust, the customer also gained additional benefits such as lower consumption and faster production cycle times.

Contact us immediately for a free consultation regarding production cost improvement programs.

Consult with EON Now

We are ready to listen and provide the right chemical solution for you. Consultation with our experts is free!

Home

Home