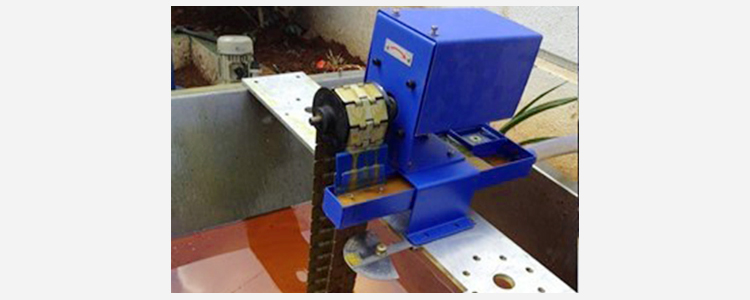

Metalworking fluid or coolant for CNC machines that has been contaminated by tramp oil, as shown in the image above, must be cleaned immediately. If not, bacterial problems will arise, causing significant losses. Bacteria must be a top concern in the application of metalworking fluids (coolant).

Types of Bacteria

Bacteria are of two types: aerobic bacteria and anaerobic bacteria. Aerobic bacteria require oxygen for their development. They reproduce by dividing every 20-30 minutes. Below is a simulation of aerobic bacteria growth over 12 hours.

1 Jam 8

3 Jam 512

6 Jam 262.000

9 Jam 134.000.000

10 Jam 268.000.000

12 Jam 1.032.000.000

In addition to aerobic bacteria, there are also anaerobic bacteria that can grow without oxygen. These bacteria divide every 4 hours and typically grow after the coolant in the machine has been contaminated by aerobic bacteria. Controlling bacterial growth is crucial for successful coolant management.

Tramp Oil Skimmer

Tramp Oil as Bacterial Food

Tramp oil is one of the food sources for bacteria. Therefore, bacteria can grow quickly in machines with leaking oil tanks (which contain a lot of tramp oil). This is why tramp oil should be cleaned immediately.

Bacterial Problems

Bacteria can reduce the performance of the coolant. SRB (Sulphate Reducing Bacteria) can cause corrosion problems and unpleasant odors, such as the smell of rotten eggs. This is because SRB activity produces H2S, which smells like rotten eggs. H2S is acidic and can cause corrosion problems. Additionally, these bacteria can turn the coolant in the machine tank black if iron is present.

The more bacteria there are, the bigger the problems with metalworking fluids. Therefore, bacteria must be eliminated or their growth rate inhibited.

It is important to understand that only a small fraction of bacteria are contained within the coolant. Most bacteria are found clinging to the sides of the tank, at the bottom of the tank, mixed with chips, and even in the machine pipes.

How to Control Bacterial Growth

Here are some measures that can be taken to address metalworking fluids issues, particularly to reduce bacterial growth rates:

- Use metalworking fluids/coolant that contain biocides, or add biocides to the tank as needed

- Use an oil skimmer in the coolant tank to remove tramp oil, which is a food source for bacteria

- Control the application of metalworking fluids according to procedures, such as ensuring the correct concentration

- Use low-mineral water or, even better, deionized water, as minerals are also a food source for bacteria

- Regularly control tramp oil and check pH levels

- Keep the machine clean, and remove chips from the machine

Masalah Jamur

Fungal Problems

Fungi make the machine and coolant dirty. Fungi growing at the bottom of the tank are better cleaned mechanically rather than using chemicals. Biocides and fungicides cannot perfectly clean fungi at the bottom of the tank.

In general, minerals contained in water are a food source for fungi. Therefore, using pure or low-mineral water also helps minimize fungal growth.

It is worth noting that synthetic coolants are more susceptible to fungal attacks compared to emulsion coolants. Meanwhile, emulsion coolants are more prone to bacterial attacks compared to synthetic coolants.

Reff. Technical Bulletin Master Fluid Solution.

For further consultation, please contact us

Consult with EON Now

We are ready to listen and provide the right chemical solution for you. Consultation with our experts is free!

Home

Home