In the oil & gas industry, there are several divisions, including the maintenance division and the logistics or warehouse division. The maintenance division is responsible for the upkeep of units and components within the oil & gas industry. The warehouse division is responsible for the storage and management of industrial supplies. During operational processes, objects frequently fall or spill onto the floor. This can cause the floor to crack and develop holes.

Solution

The solution to address and prevent issues of cracked or pitted floors when objects fall or spill onto the floor is to apply an impact-resistant and chemical spill-resistant epoxy coating.

Concrete floors become pitted due to frequent falling of work objects

Success Story

Our customers across Indonesia often face problems with pitted concrete floors. This poses a challenge when it comes to coating. To address this issue, Eonchemicals provides a solution with the products EonCoat 551 Primer and EonCoat 551 SF.

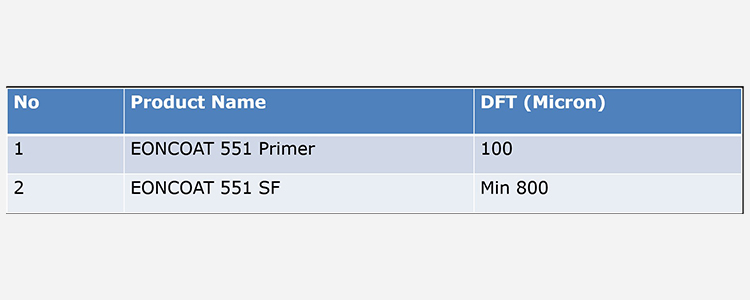

EonCoat 551 Primer is an epoxy-based base coating that functions as an intercoat adhesion (intermediate binder) between the concrete floor and the top coat. EonCoat 551 SF, on the other hand, is a solvent-free epoxy coating that serves as the top coat, providing optimal protection when the floor is exposed to chemical spills or falling work objects.

Additionally, this product can also level out already pitted floor surfaces.

After application of EonCoat 551 SF on the perforated floor

Coating System Epoxy Solvent Free

Advantages :

- Resistant to falling work objects

- Resistant to chemicals

- Can level concrete floors

- Oil and grease do not absorb into the concrete

For free consultation on this type of coating, please contact us.

Consult with EON Now

We are ready to listen and provide the right chemical solution for you. Consultation with our experts is free!

Home

Home