Neatness, cleanliness, and safety are three essential aspects to consider in the power generation industry. One of the crucial elements is the condition of the concrete floors. Typically, the concrete floors in power plants are coated from the time they are first constructed. Over time, as the plant operates, the floor coating can crack and even develop holes.

Solution

The way to prevent or address cracked and holed concrete floors is by periodically applying an epoxy coating.

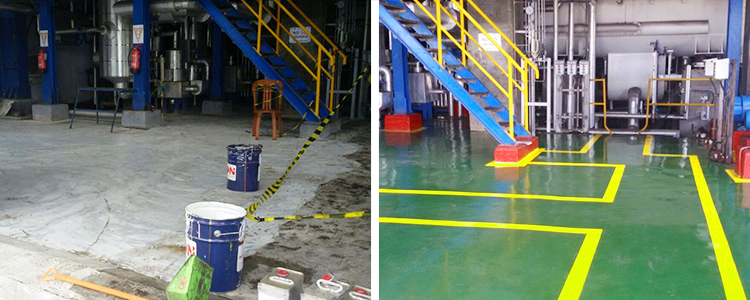

Unprotected condition of concrete floor in one of the plants

Success Story

A power generation company once faced issues with cracked and holed concrete floors. Eonchemicals provided a solution by applying the EonCoat 551 Series :

- EonCoat 551 Primer is an epoxy-based primer that acts as an intercoat adhesion layer between the concrete floor and the top coating layer.

- EonCoat 551 is a solvent-based epoxy coating that serves as the top coat, providing optimal protection when the floor is exposed to chemicals or oil spills.

- EonCoat 551 SF is a solvent-free epoxy coating that serves as the top coat, offering optimal protection against chemical and oil spills, falling objects, and leveling the surface of holed floors.

Before and after application

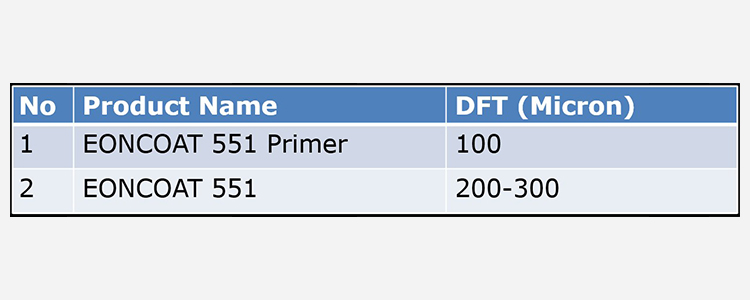

Epoxy Solvent Based

Advantages:

- Ideal for floors without holes

- Oil does not penetrate the concrete

- Good chemical resistance

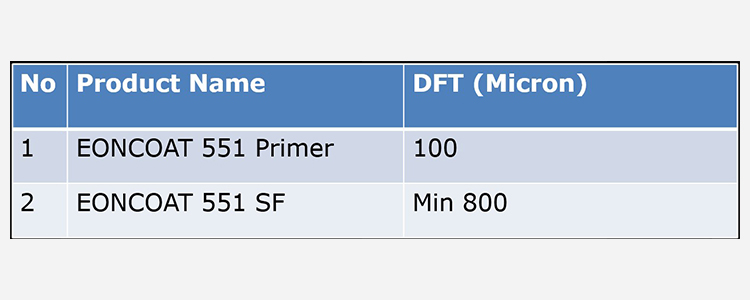

Epoxy Solvent Free

Advantages:

- Resistant to falling objects

- Ideal for holed floors (can level the concrete floor surface)

- Excellent chemical resistance

- Oil does not penetrate the concrete

Contact us for a consultation on epoxy coating applications at your site!

Consult with EON Now

We are ready to listen and provide the right chemical solution for you. Consultation with our experts is free!

Home

Home