How can we control grease usage in the new normal? What is the right grease pump? How can we avoid wasting grease? How can we ensure that all regreasing is done timely and not too frequently?

Are you also facing these issues? Don’t worry… you will find the solution here! At the bottom of this article, there is a success story that is important to note. One thing is certain: missing regreasing often leads to bearing damage in machine components, while regreasing too frequently is wasteful. Both of these issues can inflate your costs, right?

Let’s explore some important points…

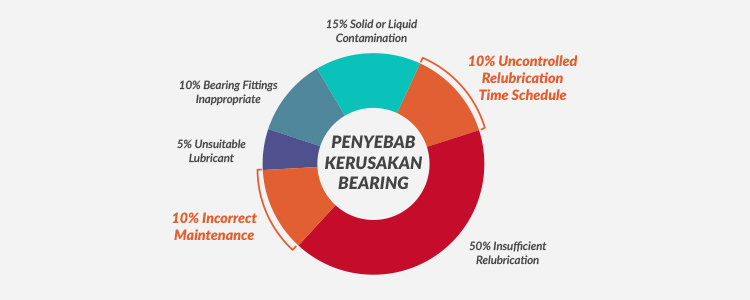

Causes of Bearing Damage

Did you know that 10% of bearing damage is due to poor lubrication control? This not only incurs costs for bearing procurement but also causes production downtime, leading to greater company losses.

Get a solution for your business efficiency. Please CHAT WHATSAPP now.

So, can an autolubricator help solve this problem? Not necessarily! Choosing the wrong autolubricator can actually increase costs. So, what is the right solution to optimize grease usage and reduce lubrication maintenance costs?

The Impact of Choosing the Wrong Autolubricator

Be cautious; many offer cheap and guaranteed autolubricators. But when problems arise, claiming the warranty is difficult. The process is tedious and full of excuses. Meanwhile, the losses due to downtime are unavoidable. This is the serious impact of choosing the wrong autolubricator.

Various other problems experienced by companies using the wrong autolubricator include:

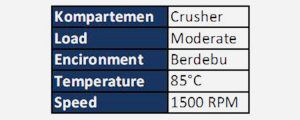

- The autolubricator is not supported by Minimum Quantity Lubrication (MQL) calculations, so the dosage used sometimes does not match the Load Environment Temperature Speed (LETS) data, causing bearings to be more easily damaged.

- No warranty or bonus battery, and if purchased, the price is quite expensive.

- No indicator for lubrication control, making it difficult to know if the autolubricator is functioning when problems arise.

- The cartridge cannot be replaced, so if the grease runs out, you have to buy a whole new autolubricator set

These issues lead to high maintenance costs!

Solution

Eonchemicals is ready to provide solutions by recommending the right autolubricator for you. Experts will assist you in solving lubrication-related problems such as:

- Field survey

Eonchemicals has many branches spread across Indonesia, so the nearest branch can reach your industrial location more quickly - Online meeting consultation

- Cost-saving proposal

Eonchemicals will provide data on the amount of cost that can be saved by using the Eonlube autolubricator

Eonlube is one of the competitive autolubricator or automatic grease pump brands alongside world-renowned brands like SKF, Lincoln, Perma, Pentastar, etc.

SUCCESS STORY

One of Eonchemicals’ customers has 60 crusher machines, with a grease top-up interval of every 3 days and 6 lubrication personnel. Before using Eonlube, the company often experienced bearing failures due to missed grease top-ups.

SOLUSI DAN HASIL

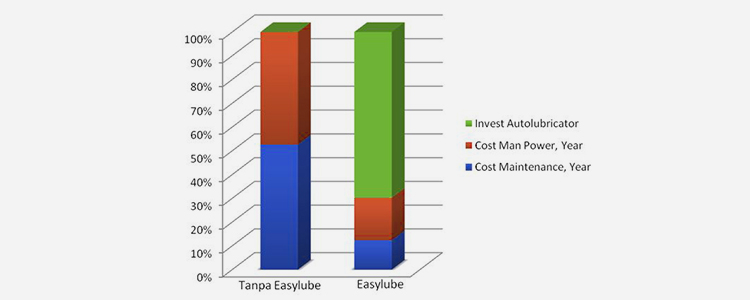

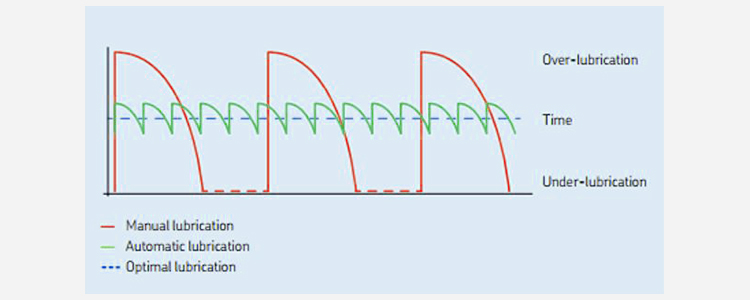

Based on the study of Eonlube usage in the crusher compartment of the company (see graph above), it shows that Eonlube can reduce Maintenance Costs by up to 40% and Manpower Costs by up to 25% per year.

Why is there significant savings? Look at the graph below….

With the Eonlube automatic grease pump, grease consumption is highly controlled.

Seeing this graph gives you peace of mind, right? Let’s make improvements in your company to optimize grease usage, extend bearing life, and save costs!

Eonlube

Eonlube is a single-point autolubricator supported by MQL features, providing a simple and logical formula to determine lubricant volume and top-up intervals. Suitable for various machine components in industries such as power plants, food, animal feed, palm oil mills, refineries, mining, oil and gas, automotive, petrochemicals, electronics, pharmaceuticals, manufacturing, pipelines, pulp & paper, etc

Consult with us (free) for solutions and business efficiency. Please CHAT WHATSAPP now.

Suitable conditions for using Eonlube single point:

- Machines that cannot stop for regreasing

- Hard-to-reach bearings

- Bearings that need repeated lubrication but are in hazardous environments (dusty, high-speed, acidic, alkaline, high temperature, noisy, wet, heavy load)

- Expensive imported bearings

- Very suitable for the food & beverage industry, which is concerned about cleanliness

Eonlube can provide the best performance in controlling grease top-up intervals with the right grease usage dosage (not less & not more). It is very easy to apply, easy to monitor, and minimizes maintenance costs, thereby reducing maintenance costs and minimizing production downtime.

FREE BATTERY WITH EVERY CARTRIDGE PURCHASE!

If you have lubrication problems and want to improve to save costs in your department, please chat with us on WhatsApp, PT Eonchemicals Putra now.

Consult with EON Now

We are ready to listen and provide the right chemical solution for you. Consultation with our experts is free!

Home

Home