In the steel industry, corrosion that appears on the surface of coils necessitates a re -pickling process to clean them. This process results in a reduction of the coil’s weight, thereby decreasing its selling price. A more severe effect is the downgrading of the coil’s grade, which can lead to rejection.

Generally, the steel industry uses Rust Preventive Oil (RPO) as a temporary coating to prevent rust. The problem is that many types of RPO are difficult to remove, making it quite challenging when the coil needs to be cleaned for further processing.

Corrosion of steel coils during storage

Solution

The right solution for addressing the problem of steel coil corrosion is to use an anti-corrosion agent that has the following properties:

- Capable of preventing long-term corrosion (12 months)

- Easy to clean thoroughly, so it does not interfere with the subsequent processing of the coil

Success Story

To meet the needs of the steel industry, Eonchemicals presents a special RPO product, EonFilm 750. This product is robust in protecting steel coils from corrosion for up to 12 months, yet easy to clean when the coil is ready for further processing.

EonFilm 750 has long been trusted by customers in the steel industry to this day, as it continues to provide product innovation and improvement according to the processes and RPO requirements suitable for steel coil production systems in the field.

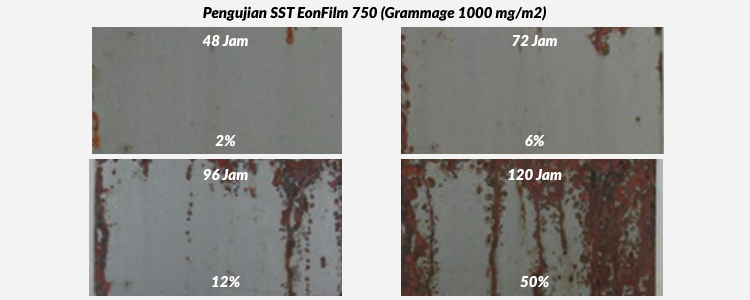

Results of SST test on EonFilm 750 in resisting rust

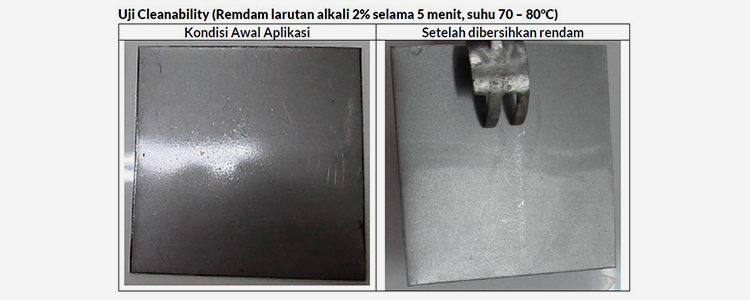

Results of cleanability test of EonFilm 750 in 2% alkali

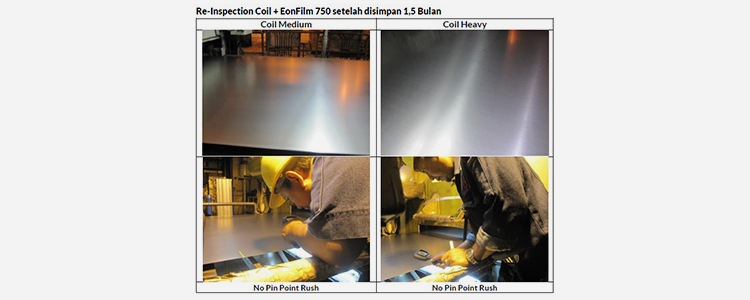

Inspection of EonFilm 750 application results with customers

Consult with EON Now

We are ready to listen and provide the right chemical solution for you. Consultation with our experts is free!

Home

Home