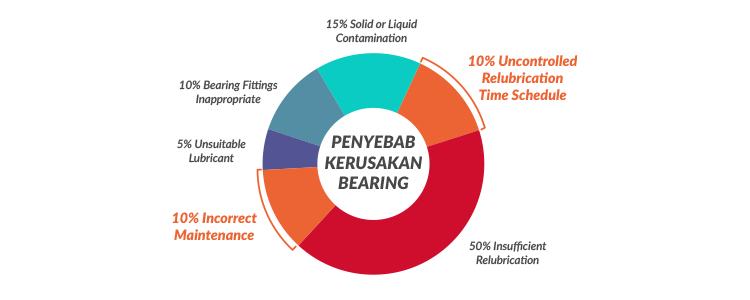

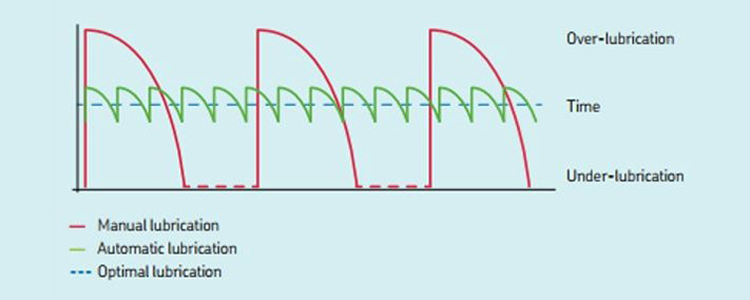

Regreasing is one of the core aspects of conveyor maintenance, particularly manual regreasing. This process has become a common issue in many mining companies. Over-frequent regreasing can lead to excessive consumption, while insufficient regreasing results in inadequate lubrication. Here are the data on bearing damage causes:

- 50% due to insufficient lubrication

- 10% due to uncontrolled regreasing intervals

- 20% due to improper grease selection and grease contamination

If these issues are not properly addressed, up to 80% of potential bearing damage can occur, hindering productivity.

Solution

Eonchemical provides autolubricators equipped with technology to calculate Minimum Quantity Lubrication (MQL) by considering load, environment, temperature, and speed (LETS).

These technical calculations are necessary to ensure that the installed autolubricator operates optimally. EonLube is a technology developed to assist in conditions where:

- Machines can operate continuously, even during the regreasing process

- Regreasing is facilitated at hard-to-reach points

- Regreasing intervals are precise, and the dosage is minimal

Success Story

One of our customers has 60 crusher units with a regreasing interval of every 3 days, requiring a workforce of 6 people. This company previously experienced frequent bearing failures due to missed regreasing.

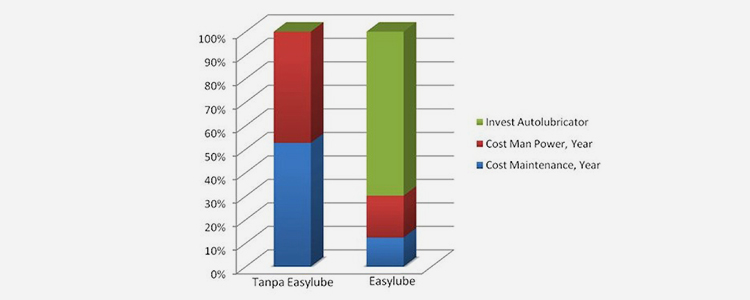

To address this problem, Eonchemicals provided a solution with EonLube. This solution successfully delivered annual cost savings as follows:

- 50% reduction in manpower costs

- 40% reduction in maintenance costs

These savings were achieved thanks to the Minimum Quantity Lubrication technology embedded in EonLube.

For a lubrication savings program with EonLube, please contact us.

Consult with EON Now

We are ready to listen and provide the right chemical solution for you. Consultation with our experts is free!

Home

Home