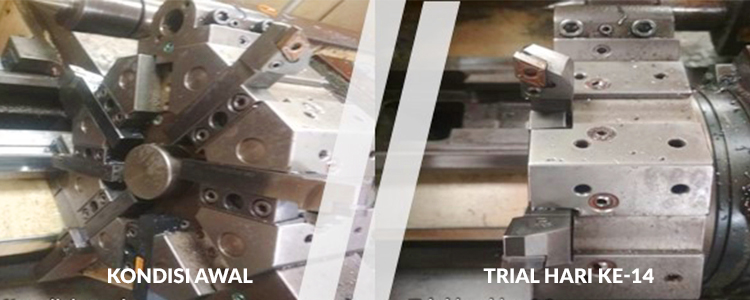

CNC (Computer Numerical Control) machine maintenance requires serious attention. These machines are used for metalworking processes such as turning, drilling, and cutting metal. A common issue with CNC lathes is corrosion on machine parts.

For instance, a company in Palembang experienced rapid corrosion on CNC machine parts. Within 1 to 3 days after parts were replaced or maintained, visible corrosion appeared. This is highly detrimental as it forces users to perform CNC machine maintenance and part replacements more frequently, thereby reducing productivity and increasing operational costs.

Solution

To address this issue, we conducted a field trial using the EonTrim C385 lathe coolant. The specifications of this coolant are as follows:

- Light yellow in color, clear, and low-foaming, allowing the lathe object to be clearly visible

- Contains a corrosion inhibitor, effectively protecting CNC machine parts from corrosion issues

Coolant Application

- For light to moderate duty, EONTRIM C385 can be applied at a concentration of 5-7%

- For moderate to heavy duty, EONTRIM C385 can be applied at a concentration of 7-10%

Trial Results

Up to the 14th day of the EonTrim C385 trial, no rust was found on CNC machine parts. Previously, rust problems would appear within the first to third days.

Conclusion

Based on the field trial results, EonTrim C385 has proven to offer significantly longer protection compared to the previously used coolant.

Thus, users can save time and effort in maintaining CNC machines. Maintenance costs decrease, and productivity increases.

This has led to user satisfaction, and they recommend using EonTrim C385 metalworking fluid for their CNC machine maintenance.

Please contact us for further information

Consult with EON Now

We are ready to listen and provide the right chemical solution for you. Consultation with our experts is free!

Home

Home