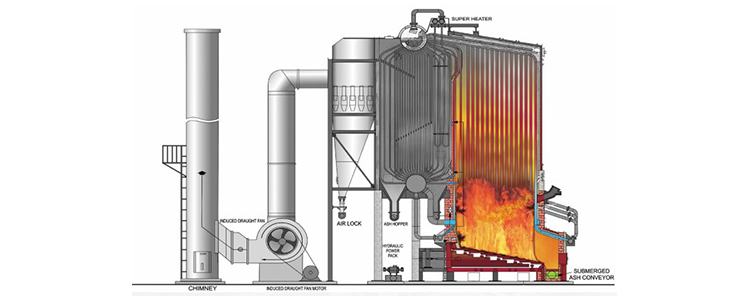

Boilers are a very important part of the palm oil mill. To ensure and keep the boiler at maximum or efficient performance, it is necessary to carry out maintenance to avoid problems in the boiler combustion chamber. The characteristic of an efficient palm oil mill boiler is that it can produce residual shells that can be sold as an additional profit..

The problems that often occur due to lack of boiler combustion efficiency are as follows:

- Incomplete, inhomogeneous combustion and unburnt shells remain

- Black combustion smoke

- Combustion flame is not hot enough, visually less bright

- There is no palm kernel shell residue, because it is all used up as boiler fuel (or only a little left)

- There is slug/crust that comes from the remaining combustion products that stick to the pipe

- Due to the presence of slug / crust, heat transfer is less efficient

- High flue gas temperature in the boiler chimney, due to inefficient heat transfer

Solusi

Eonchemicals presents EonCatalyst B5555, a product designed to enhance combustion efficiency in boilers. This solution contains MgO and NH3 as slag ash modifiers and corrosion inhibitors, as well as CaO and CuO as combustion improvers. The features and benefits include:

- Sublimation with NH3 at 350°C

- Formation of a thin layer on the walls

- Reduction of fly ash acidity levels

- Sublimation along the flue gas path

- Contains slag removal and corrosion inhibitors

- Modifies deposits to be more porous

- Increases melting point, thereby reducing the potential for slag formation

- Lowers the activation energy for combustion

- Accelerates the combustion of volatile content in fuel and hydrocarbons.

Success Story

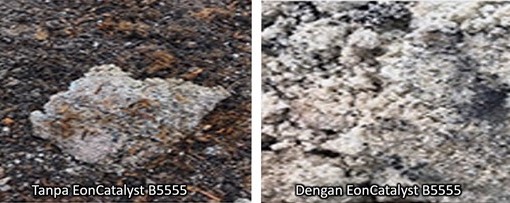

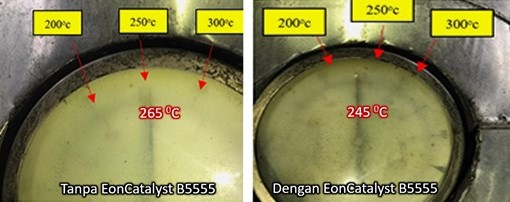

Here is a success story from a trial of EonCatalyst B5555 with one of our customers. The photo on the left shows the condition before using EonCatalyst B5555, while the photo on the right shows the condition after using the solution..

With EonCatalyst B5555, the combustion residue is more homogeneous and complete

With EonCatalyst B5555, combustion smoke is whiter

With EonCatalyst B5555, brighter flames

With EonCatalyst B5555, shell residue increased by 280 Kg/hour

With EonCatalyst B5555, the exhaust gas temperature dropped by 20 deg. C

Conclusion

By using EonCatalyst B5555, you will gain the following benefits:

- More complete combustion, no slug formation

- Cleaner exhaust smoke, less air pollution

- Brighter flame, hotter combustion chamber

- More shell residue, more profitable

- Lower exhaust gas temperature (due to increased heat utilization efficiency)

For a free consultation on boiler combustion chamber efficiency issues and solutions, please contact us.

Consult with EON Now

We are ready to listen and provide the right chemical solution for you. Consultation with our experts is free!

Home

Home