This is the success story of the Molykote BR2 Plus lubricant trial in one of the palm oil mills. After visiting the site, observing, and conducting tests to improve the existing system, one of the machines that caught our attention was the fiber cyclone fan.

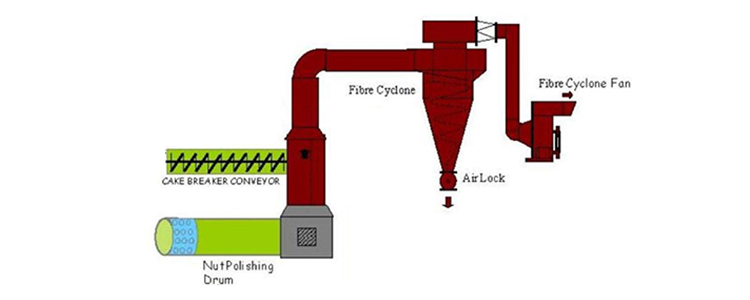

The Fiber Cyclone Fan functions to draw in a sufficient amount of air to lift the fiber from the Depericarper to the Fiber Cyclone. The fan used operates with medium to high pressure.

Field Problems

The problem identified was that high load and rotation speed caused the temperature in the bearing housing to rise quickly. This resulted in the grease melting because they were not using high-temperature grease. Another issue was that the existing grease was too expensive.

Technical Data

During the field observation, the following technical data were obtained:

- Regreasing interval: every 2 weeks

- Load: 300 – 350 kg

- Environment: Normal

- Temperature: 70°C – 80°C

- Speed: 1500 RPM, ID: 65 mm

Solution

Considering the problems and technical data obtained, the Eonchemicals team provided a solution by applying Molykote BR 2 Plus lubricant with the following characteristics:

- Load: Medium – High

- Environment: Acidic (Palm Oil Mill)

- Temperature: Covers up to 130°C

- Speed: Medium to high-speed bearing/open gear

Molykote BR2 Plus Trial Procedure

- Clean the bearing from the existing grease

- It is recommended to use Eonsolv 135

- Ensure the bearing is dry before filling

- Fill the bearing with Molykote BR2 Plus evenly, including the roller bearing parts.

Trial Results Over 2 Weeks

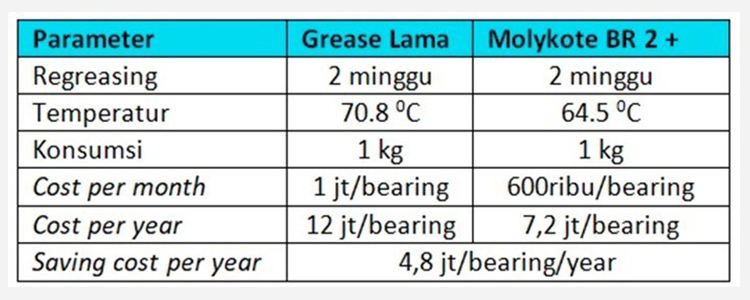

There are 2 bearings for each fiber cyclone fan machine. Total cost savings: IDR 9.6 million per unit per year.

Conclusion

From the field trial data over 2 weeks as shown in the table above, the following conclusions were drawn:

- Molykote BR2 Plus grease did not melt after 2 weeks of application on the Fiber Cyclone Fan bearing

- Bearing temperature was 6.3°C cooler compared to before

- Total cost savings using Molykote BR 2 Plus was IDR 9.6 million per unit per year

- Tool savings: with Molykote BR2 Plus, the bearing does not heat up quickly (lasts longer)

Consult with EON Now

We are ready to listen and provide the right chemical solution for you. Consultation with our experts is free!

Home

Home