Straight oil is a type of metalworking fluid or pure lubricant oil (100% oil) used without mixing with water or other solvents. This lubricant is also known as neat oil or neat cutting oil or neat cutting lubricant. Common problems encountered when using this product include:

- The formation of mist during the cutting process

- Neat oil turning black

Solutions

The right solution can only be provided if the cause of the problem is correctly identified. Below are the factors causing these problems and their solutions.

Formation of Mist

Cause: Straight oil or neat oil has insufficient cooling capacity, causing the machine to heat up more quickly.

Solution: Use straight/neat oil with low “oil mist” properties, low viscosity, and low volatile oil content, so that it does not produce mist at high speeds.

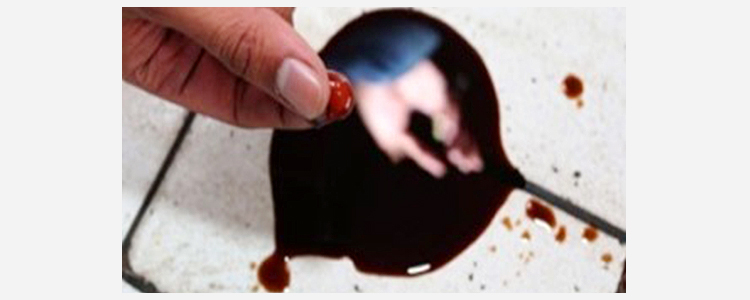

Oil Turning Black

Cause: Contamination from the machine, processing materials, or other dirty oils that cause the oil’s function to deteriorate, as well as inadequate machine maintenance (usually occurs in older machines).

Solution: Check the viscosity using a viscometer and compare it with the condition of fresh neat oil. If there is a difference (between the viscosity of fresh neat oil and the used neat oil), immediately drain the machine until all contaminants are removed.

Note: It is very important to conduct regular checks to understand the condition of the machine and to minimize unnecessary costs in maintaining lathes with straight oil or neat oil.

For further consultation, please contact us.

Consult with EON Now

We are ready to listen and provide the right chemical solution for you. Consultation with our experts is free!

Home

Home