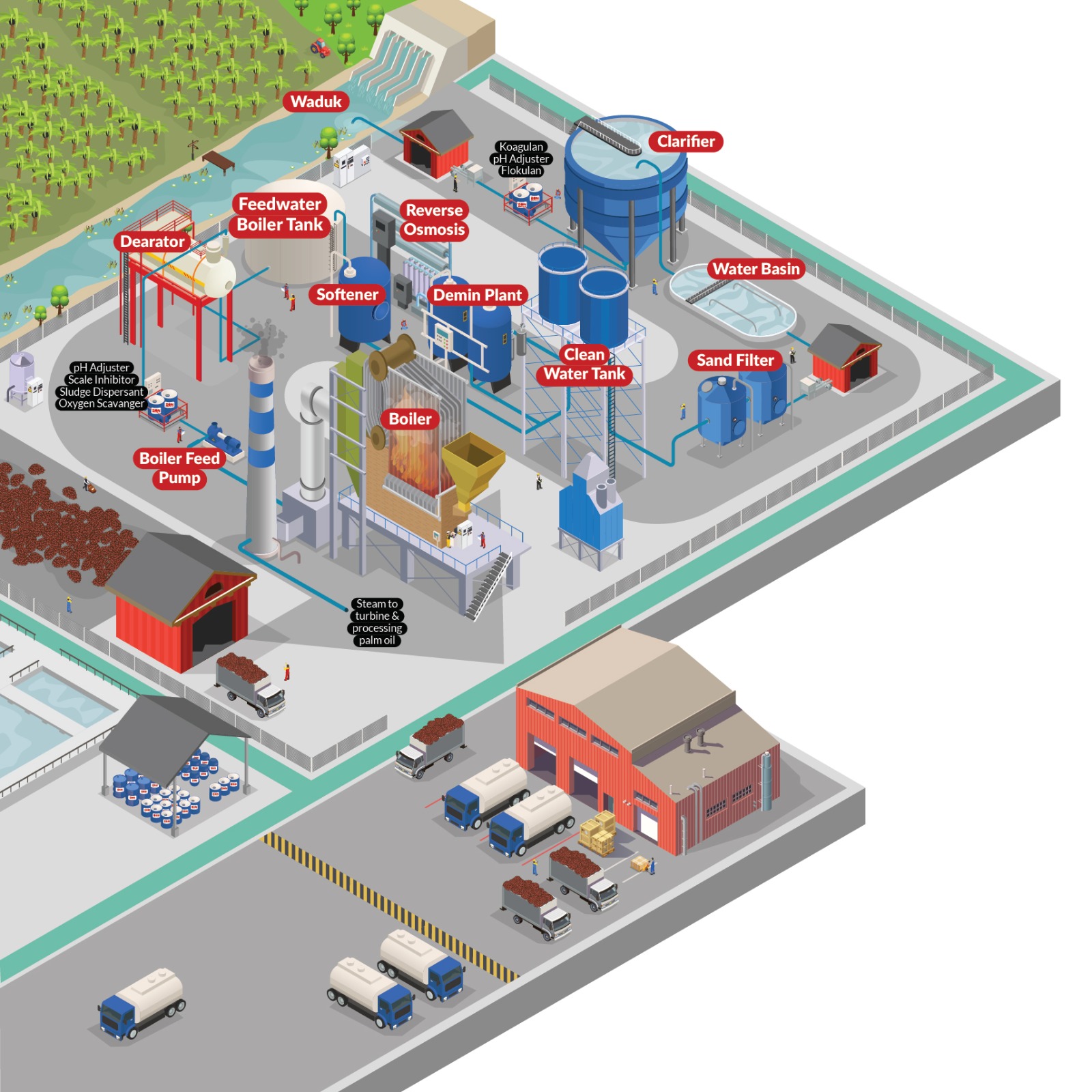

In the palm oil production process, the use of water purifiers and boilers is crucial to support operational efficiency and sustainability. Water purifiers are employed to ensure the quality of water used in the production process and to manage liquid waste to prevent environmental contamination.

Meanwhile, boilers play a role in generating the steam and heat needed for various processing stages, such as fruit sterilization and oil purification. The use of this technology not only enhances production efficiency but also helps reduce environmental impact, ensuring that the industry can operate more sustainably in the future.

Palm Oil Industry Process Illustration

Tips: Use two fingers to zoom in on the image

Palm Oil Industry Problem and Solutions Table

Click the link in the “Equipment” column to see the details.

| No | Equipment | Problem | Solution |

|---|---|---|---|

| 1 | Clarifier Equipment | Water Turbidity, Floating Flocs | Coagulant Water Clarifier Floculant Water Clarifier pH Adjuster Eon Training |

| 2 | Sand Filter Equipment | Water Turbidity | Silica Filter Activated Filter Media |

| 3 | Softener Equipment | Loose Hardness | Cation Resin Resin Cleaning Eon Training |

| 4 | Demin Plant Equipment | Loose Hardness | Cation Resin Resin Cleaning Eon Training |

| Loose Silica | Anion Resin Resin Cleaning Eon Training | ||

| 5 | Reverse Osmosis Equipment | Decreased Reverse Osmosis Performance | Biocide Dechlorinator Chemical Anti Scalant Organic RO Membrane Cleaner Inorganic RO Membrane Cleaner |

| 6 | Boiler Equipment | Scale, Corrosion, Carry Over | Scale Inhibitor Online Cleaning Chemical Oxygen Scavenger pH Adjuster |

| Slag in the Combustion Room | Catalyst for Shell and Fiber |

Home

Home