The pipe industry in Indonesia plays a key role in supporting the energy, infrastructure, and construction sectors. It is not uncommon for issues such as corrosion and leaks to become significant concerns, necessitating regular maintenance.

To assist in the maintenance process of pipes and to undertake preventive actions, we provide chemical solutions that help extend the lifespan of pipes, enhance operational efficiency, and reduce maintenance costs.

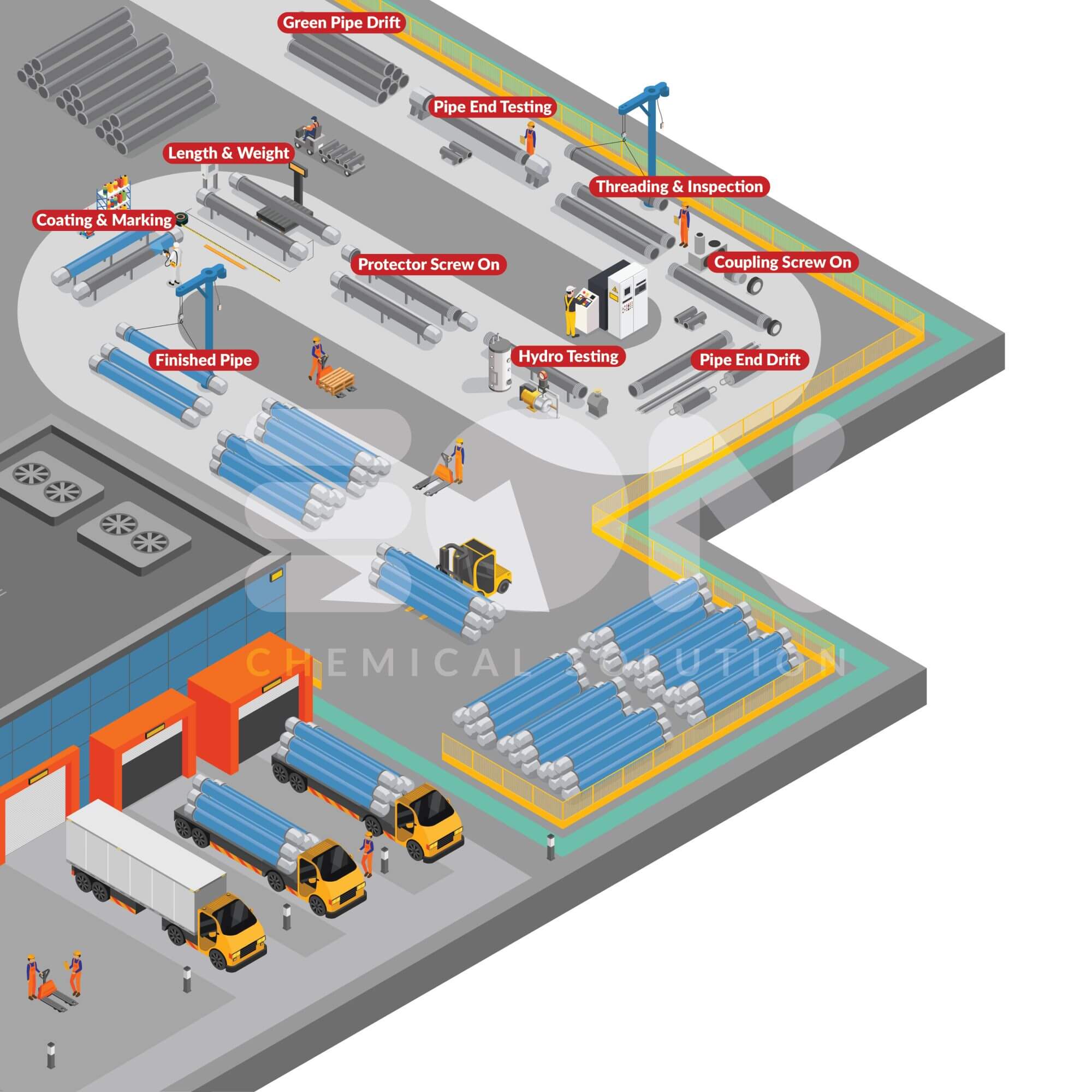

Pipe Industry Process Illustration

Tips: Use two fingers to zoom in on the image

Pipe Industry Problem and Solutions Table

Click the link in the “Equipment” column to see the details.

| No | Equipment | Problem | Solution |

|---|---|---|---|

| 1 | Threading & Inspection | Coolant Problem (Tramp Oil, Rust, Residue, Chips, Smell) | Micro Emulsion Coolant |

| Fire Resistant Hydrolic Oil | EonHydra | ||

| 2 | Hydro Testing | Pitting Corrosion | EonTrim PHT |

| 3 | Coating & Marking | Coat for Marking | Stencil 108 |

| Corrosion on Coupling | EonCoat for Coupling | ||

| Corrosion White Storage on External Surface | EonCoat Series | ||

| 4 | Finished Pipe | Thread & Internal Corrosion in Storage | Internal Coating Storage Compound |

Home

Home