As the market demand for high-quality animal feed increases, the feed mill industry must enhance the quality of its supporting factors in both production processes and machine maintenance. One essential supporting factor is the use of heat-resistant lubricants certified as food grade.

Moreover, the lubricants applied to pelletizer machines in a feed mill must withstand heavy loads and possess halal/halal grease certification to support and ensure the implementation of ISO 22000. It is crucial to note that feed mills not using heat-resistant and food-grade lubricants often face several detrimental issues.

Problems. Here are some problems that can arise from not using the appropriate lubricants (grease):

- Grease melting due to the absence of heat-resistant lubricants

- Resulting in the need for more frequent regreasing

- The more frequent the regreasing, the higher the costs for grease procurement (inefficient)

- Bearings in the pelletizer machine wear out quickly

- Consequently, bearings need to be replaced sooner than expected

- The quicker the bearing replacement, the higher the costs for bearing procurement and the longer the downtime/lost production that must be endured

- Not using food-grade grease means failing to comply with Food Safety ISO 22000

- As a result, the products you produce may not be safe for consumption, potentially leading to customer complaints

- Ultimately, operational costs increase while customer trust diminishes

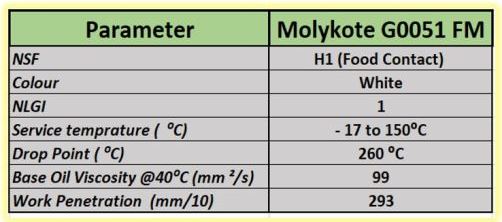

Solution. To address these highly detrimental issues, the use of Molykote G-0051 FM is recommended. This is a superior heat-resistant lubricant from Eonchemicals with the following benefits and features:

- High heat resistance, up to 150 deg. C

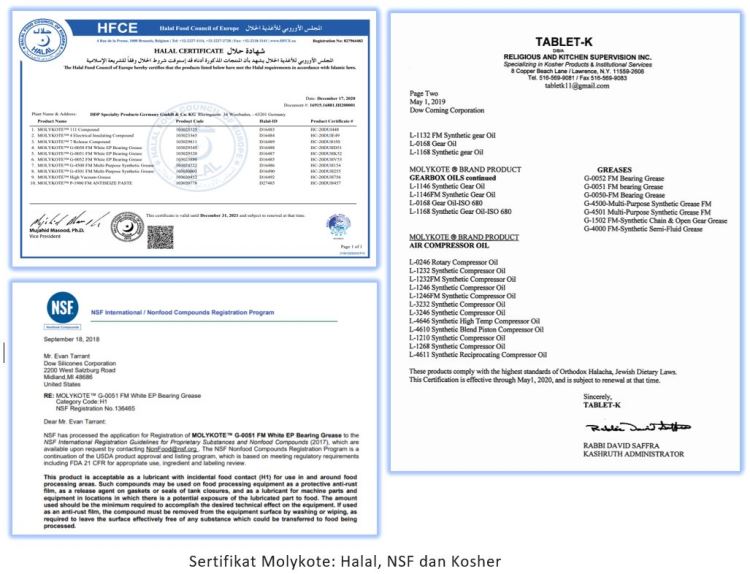

- Food-grade grease NSFH-1

- Halal and Kosher certified

- Supports the implementation of ISO 22000 in feed mills/pellet mills

- High adhesion

- Water-resistant

- High load capacity

- Suitable for pelletizer machines

Eonchemicals has long provided solutions with Molykote G-0051 FM to many animal feed industries/feed mills in Indonesia. They continue to use this product because it reduces factory operational costs and meets other essential needs. A related article you might need to know about is the appropriate O-ring lubricants for the industry.

Success Story Cost Savings Up to 71%

For further consultation on reducing operational costs and implementing ISO 22000 with high heat-resistant, food-grade, and halal lubricants, please chat with us on WhatsApp now.

Consult with EON Now

We are ready to listen and provide the right chemical solution for you. Consultation with our experts is free!

Home

Home