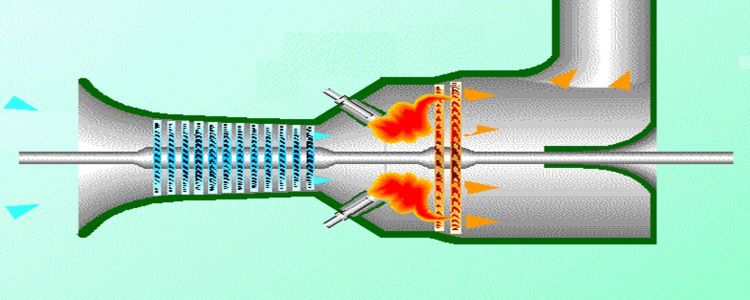

This article summarizes the field trial for gas turbine compressor cleaning at one of Eonchemicals’ customers, using Turboklin 500, a turbine compressor cleaner as previously described in another article.

During the crank soak wash activity on the gas turbine compressor (GTC) engine, samples were taken both during the soap (soaping) and rinse processes. Here is the complete gas turbine compressor cleaning procedure using the crank soak wash method:

- 2.3 liters of Turboklin 500 were dissolved in DM water (demineralized water) at a ratio of 1:4

- The injection process was carried out by rotating the engine up to 20% speed, for 5 minutes, then left to sit for 30 minutes and samples were taken (soap process)

- Then, rinsing was done using demineralized water for 5 minutes and samples were taken (rinse process)

- Steps 2 and 3 were repeated 3 times, after the third soap process, the rinse process was repeated several times depending on the quality of the samples

Field Trial Observation Results The use of Turboklin 500 for the gas turbine compressor cleaning process was able to clean the carbon deposits attached to the turbine blades. This was evidenced by the samples collected during the soap and rinse processes becoming progressively cleaner as shown in the images below:

Engine Performance Observation Results From the internal engine observations (contamination factors) and engine performance, there was an improvement, thus restoring the engine’s ability to support the equipment driven by the turbine engine.

Please chat for more information about gas turbine compressor cleaning with Eonchemicals.

Consult with EON Now

We are ready to listen and provide the right chemical solution for you. Consultation with our experts is free!

Home

Home