Do you frequently experience low power in your heavy equipment units? Are your fuel filters often clogged and need to be replaced more frequently? The EonFuel 70 8 fuel additive is the solution. This article is a success story detailing the field application and the product’s success in assisting customers.

One of the biggest issues faced by mining owners and contractors today is the occurrence of low power in heavy equipment. This problem arises due to the low quality or cleanliness of diesel fuel used, specifically biodiesel B30/B35. Consequently, fuel filters become clogged, and deposits form inside the injectors.

When low power occurs, the unit cannot operate and requires unscheduled breakdown maintenance. In mining units, low power can reduce production efficiency, resulting in significant losses.

Recognizing the frequent occurrence of low power issues in the field, Eonchemicals offers a solution through the application of the EonFuel 708 fuel additive. The efficacy of this product has been proven by a contractor in North Kalimantan.

Objective

The objective of the EonFuel 708 fuel additive application is to reduce low power events in units within a 250 HM service interval.

Application of EonFuel 708 This product has been used by a customer in North Kalimantan:

- Date: August 20, 2023

- Unit Type: Komatsu PC 2000 Excavator

- Unit No: EK-000

- Trial Duration: 284 hours

- Quantity: 3 pails @ 20 L each

Dosage Calculation

The recommended dosage for the EonFuel 708 fuel additive application is 2000 ppm. Therefore, for 1,000 liters of biodiesel, 2 liters of EonFuel 708 are needed, calculated as follows: (2000 / 1,000,000) x 1,000 = 2

Success Parameters

The following trial parameters were agreed upon with the customer:

- Trend of reducing low power events from interval to interval within the 250 HM service

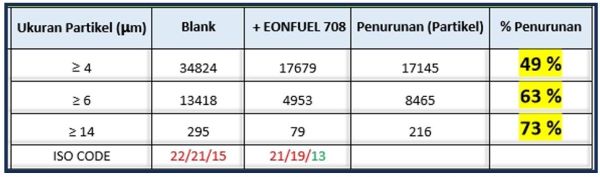

- Reducing particle content in diesel by more than 50% (ISO CODE 4406)

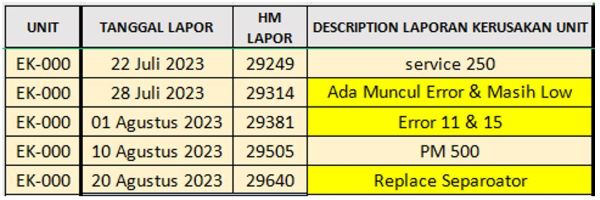

- Previously, within the service interval (PM 250 to PM 500), there were 2 low power events (errors E 11 & E 15)

- Filter lifespan was very short, requiring replacement at 138 HM (target replacement at 250 HM).

Application Results

The application of the EonFuel 708 fuel additive in North Kalimantan on the Komatsu PC 2000 over an observation period of 284 HM yielded the following results:

Cleanliness Test Results

- Before application: Particle content was very high

- After application: Particle content dropped drastically (up to 73%)

Low Power Events

- Before application: Occurred twice

- After application:** Did not occur

Deposits on Pre-filter

- Before application: Appeared at 135 HM

- After application: Slight appearance at 284 HM

EonFuel 708 successfully met the customer’s expectations in resolving their issues.

For further consultation on biodiesel problems and the application of the EonFuel 708 fuel additive, you can chat via WhatsApp by clicking the green WhatsApp button.

Consult with EON Now

We are ready to listen and provide the right chemical solution for you. Consultation with our experts is free!

Home

Home